Table of Contents

- What is an Energy Management System?

- Why is Energy Management Important?

- Understanding BS EN 16001 and ISO 50001

- Developing an Energy Management System

- Steps to Implement an Energy Management System

- Monitoring and Evaluating Your Energy Management Efforts

- Challenges in Energy Management

- Tools and Technologies for Effective Energy Management

- Frequently Asked Questions

- Conclusion

What is an Energy Management System?

Energy Management Systems (EnMS) encompass a collection of processes designed to systematically manage energy use. In simpler terms, an EnMS supports organizations in recognizing, understanding, and controlling their energy consumption. Furthermore, it facilitates the development of strategies to improve energy efficiency. While several standards exist globally, BS EN 16001 and ISO 50001 emerged as two of the most widely recognized frameworks, guiding businesses toward sustainable energy practices.

Why is Energy Management Important?

Energy management plays a crucial role in organizational efficiency and sustainability. Moreover, integrating energy management practices leads to significant cost savings and enhances an organization’s reputation. It allows organizations to reduce their carbon footprint, comply with regulations, and maintain resilience in the face of fluctuating energy prices.

By adopting an EnMS, organizations can:

- Identify opportunities for energy-saving innovations.

- Reduce operational costs through efficient energy consumption.

- Enhance compliance with national and international energy regulations.

- Contribute to corporate sustainability goals.

- Foster employee awareness and engagement regarding energy use.

Understanding BS EN 16001 and ISO 50001

BS EN 16001 and ISO 50001 provide organizations with structured guidelines for establishing and maintaining an effective energy management system. BS EN 16001, though with a more localized focus, serves as an excellent foundation for organizations operating primarily in the UK or Europe. In contrast, ISO 50001 broadens this perspective globally, making it applicable for businesses anywhere.

These standards help organizations:

- Create a culture of energy awareness.

- Consistently improve energy performance.

- Establish energy targets and objectives based on current data.

- Review and measure energy performance on an ongoing basis.

Compliance Benefits

Organizations that comply with these standards not only increase operational efficiency but also open the door for potential financial incentives through government energy efficiency programs. Additionally, demonstrating adherence boosts the credibility and competitiveness of an organization.

Developing an Energy Management System

Creating a successful energy management system begins with thorough planning and awareness of existing practices. Here are the key elements to consider:

Assess the Current Energy Performance

Commence by conducting an energy audit. This audit will help ascertain energy consumption patterns, identify areas of inefficiency, and provide a baseline for future improvements. Utilize available energy data to paint a comprehensive picture of energy use across facilities.

Engage Stakeholders

Secure buy-in from key stakeholders. Engaging employees from various levels of the organization helps foster a sense of responsibility towards energy management efforts. Conduct training and awareness programs to illuminate the importance of energy efficiency.

Steps to Implement an Energy Management System

Transitioning from a planning phase to full implementation involves several clear steps:

1. Define an Energy Policy

The energy policy needs to reflect the organization’s commitment to improving energy performance. It should state goals and provide direction for energy management efforts.

2. Set Clear Objectives and Targets

Establish specific, measurable, achievable, relevant, and time-bound (SMART) objectives that align with the overall energy policy. Pinpointing these targets facilitates tracking progress while encouraging motivation.

3. Develop and Implement Action Plans

Design action plans that specify the procedural steps needed to achieve the established targets. These should include timelines, resource allocation, and assigned responsibilities. Each action plan must be flexible enough to adapt to changing conditions.

4. Allocate Resources

Secure the necessary resources, including human capital, technology, and financial investment. Proper allocation will empower teams to take meaningful action towards energy efficiency measures.

5. Monitor and Review Energy Performance

Establish monitoring mechanisms to track energy usage continuously. Regular reviews will help evaluate whether the actions taken are moving the organization closer to its energy goals.

Monitoring and Evaluating Your Energy Management Efforts

Success in energy management does not solely depend on implementation but necessitates ongoing evaluation and adaptation. Here are significant aspects to consider:

1. Use Energy Performance Indicators (EnPIs)

Adopt energy performance indicators to assess how effectively energy is being managed. These metrics can include overall energy consumption per unit of production or square footage.

2. Regularly Communicate Results

Regular communication of results to all stakeholders helps track progress and maintain motivation. Additionally, transparency fosters ownership and accountability among teams.

3. Adjust Strategies as Needed

Be prepared to reassess strategies and targets regularly. This adaptive approach ensures that the energy management system remains aligned with organizational goals.

Challenges in Energy Management

While developing an energy management system has numerous benefits, organizations face several challenges, including:

- Resistance to change among staff members.

- Lack of expertise in strategy development and implementation.

- Inadequate data management systems to track energy consumption.

- Limited budget for energy-saving initiatives.

Tools and Technologies for Effective Energy Management

Numerous tools and technologies can aid in the effective implementation of energy management systems. Here are several of them:

1. Energy Monitoring Software

Energy monitoring systems provide real-time data regarding energy consumption, allowing organizations to identify inefficiencies quickly.

2. Automation Technologies

Implementing automation in energy systems can significantly reduce waste through optimized control of equipment and systems.

3. Training Resources

Utilizing training resources, such as the BS EN 16001 & ISO 50001 Energy Management System Training Course, provides critical knowledge to staff, enhancing the overall effectiveness of energy management strategies.

4. Data Analytics Tools

Data analytics enables organizations to mine their energy consumption data effectively. Thus, organizations can make informed decisions based on empirical evidence.

Frequently Asked Questions

What is the difference between BS EN 16001 and ISO 50001?

While both standards aim to improve energy management practices, BS EN 16001 has a more localized focus, addressing European contexts specifically, whereas ISO 50001 is a globally recognized standard that can be applied in any organization, regardless of its geographical location.

How long does it take to implement an Energy Management System?

The timeline for implementation can vary widely by organization size and complexity of operations. Typically, organizations might expect to spend several months to a couple of years developing and implementing their EnMS fully.

Can small businesses benefit from an Energy Management System?

Absolutely! Small businesses can reap significant benefits from effective energy management practices, such as reducing overhead costs and improving their overall sustainability.

Conclusion

In conclusion, developing and implementing an Energy Management System based on standards like BS EN 16001 and ISO 50001 is a vital step toward improving energy efficiency and sustainability in any organization. By assessing current energy usage, engaging stakeholders, and continuously monitoring performance, organizations can create a culture of energy awareness and accountability.

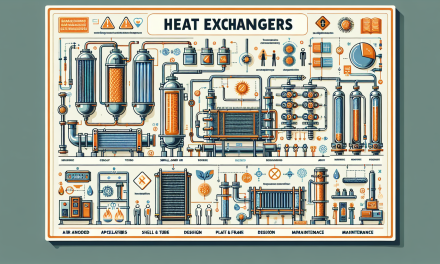

As you embark on this journey, remember that each step taken toward an energy-efficient future is beneficial for your organization as well as the environment. For more insights into energy management and its applications, consider exploring additional resources, such as Mastering Heat Exchangers, Achieving Operational Excellence, Elevating Maintenance Management, Unlocking Advanced Maintenance Management, and Comprehensive Guide to Process Plant Startup.