Table of Contents

- Introduction

- What is Big Data?

- Importance of Big Data in Maintenance Strategies

- Understanding Predictive Maintenance

- How Big Data Analytics Enhances Predictive Maintenance

- Case Studies and Real-World Applications

- Tools and Technologies Supporting Big Data in Maintenance

- Challenges in Implementing Big Data Strategies

- The Future of Big Data in Maintenance

- FAQs

- Conclusion

Introduction

In today’s rapidly evolving industry landscape, the importance of efficient maintenance strategies cannot be overstated. Organizations that leverage Big Data effectively can transform their maintenance practices, improving operational efficiency and reducing costs. This article explores the various aspects of utilizing Big Data to enhance maintenance strategies, focusing on the innovative approaches that lead to predictive maintenance.

What is Big Data?

Big Data refers to the massive volumes of structured and unstructured data that inundate a business daily. However, it is not the amount of data that matters, but what organizations do with it. In the context of maintenance strategies, analyzing this data can yield insightful information about equipment performance, failure patterns, and more. By employing advanced analytics, businesses can develop in-depth insights into their operations, ensuring more informed decision-making.

Importance of Big Data in Maintenance Strategies

Utilizing Big Data allows organizations to adopt a proactive maintenance approach. By analyzing historical and real-time data, companies can identify potential breakdowns before they occur. This foresight not only prevents unplanned downtime but also enhances the lifespan of equipment, leading to significant cost savings. Furthermore, decision-makers can prioritize maintenance tasks based on the insights derived from their data, ensuring optimal resource allocation.

Advantages of Big Data in Maintenance

The transition towards Big Data-driven maintenance comes with numerous advantages, such as:

- Improved equipment reliability

- Reduced maintenance costs

- Enhanced safety measures

- Better compliance with regulations

- Increased operational efficiency

Understanding Predictive Maintenance

Predictive maintenance is a strategy that employs data-driven insights to predict when equipment will fail or require maintenance. Instead of following a predetermined schedule or reacting to breakdowns, organizations can make informed decisions about when to conduct maintenance activities. This not only maximizes the utilization of equipment but also ensures maintenance is performed only when necessary, resulting in significant operational efficiencies.

Key Components of Predictive Maintenance

To implement predictive maintenance effectively, a few key components must be in place, including:

- Data collection: Gather data from various sources, including machinery sensors, maintenance logs, and environmental factors.

- Data storage and management: Store amassed data securely while maintaining its accessibility for analysis.

- Analytics tools: Utilize advanced analytics tools to process and analyze the data for actionable insights.

- Integration with operations: Ensure seamless integration of predictive maintenance insights into daily operational practices.

How Big Data Analytics Enhances Predictive Maintenance

Big Data analytics equips organizations with the necessary tools to uncover hidden patterns, correlations, and trends. In maintenance, analytics can help by:

- Identifying failure patterns: Advanced algorithms can detect patterns leading to failures, allowing teams to intervene proactively.

- Forecasting equipment performance: Predictive models can project performance metrics, enabling timely maintenance actions.

- Optimizing inventory management: Maintaining the right inventory levels based on predictive analytics helps reduce holding costs.

- Enhancing workforce efficiency: With strategic insights, teams can prioritize tasks and optimize scheduling.

For further insights into predictive maintenance strategies, check out the Big Data Strategies for Predictive Maintenance Course.

Case Studies and Real-World Applications

Many organizations have successfully integrated Big Data into their maintenance strategies, leading to improved outcomes. For example:

1. Manufacturing Industry

A leading manufacturing company utilized Big Data to predict machine failures, which significantly reduced their downtime. By analyzing sensor data in real-time, they could schedule maintenance during off-peak hours, ultimately boosting productivity.

2. Transportation Sector

In the transportation field, organizations are using predictive maintenance to keep fleets running efficiently. By continuously monitoring vehicle performance with IoT devices, they can preemptively manage maintenance needs, reducing both costs and service disruptions.

Tools and Technologies Supporting Big Data in Maintenance

Numerous tools and technologies can facilitate the integration of Big Data in maintenance strategies:

- IoT sensors: These devices collect real-time data from machines, allowing businesses to monitor performance continuously.

- Cloud computing: Enables the storage and processing of vast amounts of data seamlessly, making it accessible anywhere.

- Data analytics platforms: Tools such as machine learning and AI algorithms process data to provide actionable insights.

- CMMS software: Computerized Maintenance Management Systems help organizations track maintenance activities and analyze historical data.

Challenges in Implementing Big Data Strategies

Despite the numerous benefits, implementing Big Data in maintenance does come with challenges:

1. Data Quality

The success of Big Data initiatives largely depends on the quality of the data collected. Poor-quality data can lead to erroneous insights, negating the potential benefits of analytics. Organizations need robust data governance practices to ensure data accuracy and reliability.

2. Skills Gap

Another challenge lies in the skills gap within organizations. Many companies may struggle to find professionals equipped with the necessary expertise in data analytics. Investing in training programs can help bridge this gap and enhance the overall capacity for Big Data usage.

3. Integration with Legacy Systems

Integrating Big Data solutions with existing legacy systems can be complex. A strategic approach towards upgrading systems while ensuring compatibility with new data solutions is crucial.

The Future of Big Data in Maintenance

The future of maintenance strategies will undoubtedly revolve around Big Data and machine learning techniques. Organizations that harness the power of these innovations will experience increased productivity and competitive advantages in the marketplace. Additionally, the incorporation of artificial intelligence in predictive maintenance is likely to automate a significant portion of decision-making processes, further streamlining operations.

For those interested in further reading, valuable insights can be found in articles such as Mastering Building Services Management: A Comprehensive Guide and Understanding Machinery Failure Vibration Issues and Predictive Maintenance Strategies.

FAQs

What is the main benefit of Big Data in maintenance strategies?

The primary benefit of using Big Data in maintenance strategies is the ability to shift from reactive to predictive maintenance. This shift allows organizations to foresee equipment failures before they occur, enhancing equipment reliability and minimizing downtime.

How can organizations ensure data quality for effective maintenance?

To ensure data quality, organizations should implement robust data governance practices. Regular audits, standardized data collection procedures, and continuous monitoring can help maintain high data quality.

What role does IoT play in Big Data maintenance strategies?

IoT devices play a critical role in converging data streams from different machinery. This connectivity enables the continuous collection of performance data, which can be analyzed to derive actionable insights.

Are there specific tools required for implementing predictive maintenance?

Yes, various tools, including IoT sensors, data analytics platforms, and Cloud solutions, are essential for implementing predictive maintenance strategies effectively.

Conclusion

In conclusion, the integration of Big Data into maintenance strategies marks a pivotal transition in how organizations manage their operations. The utilization of predictive maintenance driven by Big Data enhances reliability, reduces costs, and increases efficiency. By being proactive rather than reactive, businesses can navigate the complexities of modern operations with greater agility. With continued advancements in technology, the future looks bright for those who embrace Big Data in their maintenance practices.

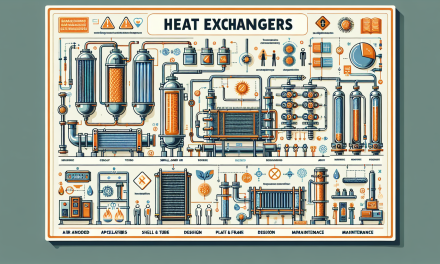

For more details on enhancing maintenance strategies, consider exploring articles such as Unlocking the Secrets of Effective Road and Infrastructure Maintenance Training and The Essential Guide to Troubleshooting Maintenance and Protection of AC Electrical Motors & Drives as well as Mastering Heat Transfer in the Process Industry: Innovative Augmentation Techniques for Optimal Efficiency.