Table of Contents

- 1. Introduction

- 2. Understanding Centrifugal Compressors

- 3. Mechanisms and Applications

- 4. Exploring Steam Turbines

- 5. Steam Turbine Design and Usage

- 6. Energy Efficiency Optimization

- 7. Benefits of Certification

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction

When it comes to industrial processes and energy generation, centrifugal compressors and steam turbines play pivotal roles. These machines are not just integral components of various systems; they also enhance efficiency and productivity across numerous sectors. Understanding how they work and their applications can significantly boost an individual’s career in engineering and related fields. This guide offers insights into centrifugal compressors and steam turbines, focusing on their mechanisms, applications, and how mastering these concepts can lead to certifications that set professionals apart in the marketplace.

2. Understanding Centrifugal Compressors

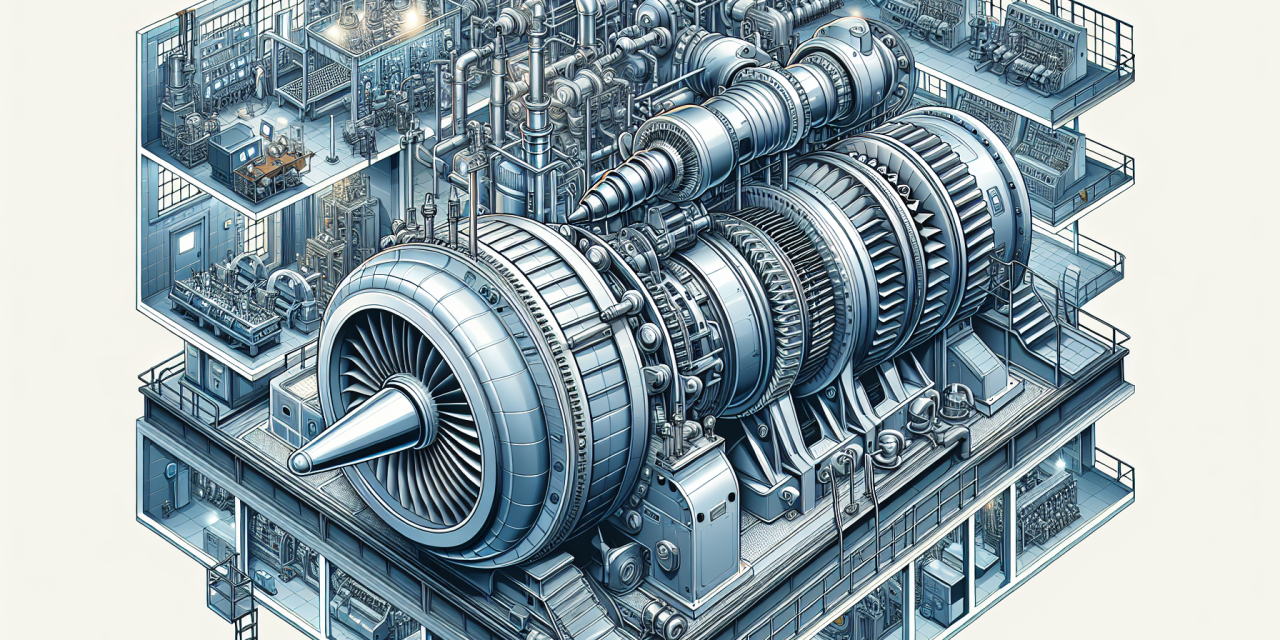

Centrifugal compressors are vital for compressing gases and boosting the pressure of the air or any gas involved. Unlike reciprocating compressors, which use pistons, centrifugal compressors utilize rotating impellers to move air through the system. This design allows for consistent and efficient air movement, leading to lower energy costs and higher output.

2.1 The Mechanics Behind Centrifugal Compressors

To better understand the functionality of these compressors, consider the following components:

- Impellers: These are rotating blades that increase the velocity of the gas.

- Diffusers: Located after the impeller, they convert kinetic energy into pressure.

- Casings: They provide structural support and contain the flow of gas.

2.2 Diverse Applications of Centrifugal Compressors

Centrifugal compressors find applications in numerous environments, such as:

- Air conditioning systems

- Gas turbines

- Petroleum refining

- Natural gas transportation

Clearly, their versatility enhances operational efficiency in a variety of industries.

3. Exploring Steam Turbines

Steam turbines, on the other hand, convert the thermal energy of steam into mechanical energy. This conversion happens when steam passes through turbine blades, causing them to rotate. Steam turbines are critical in generating electricity, especially in power plants, making them indispensable in the modern energy landscape.

3.1 Components of Steam Turbines

The essential parts of a steam turbine include:

- Nozzle: It directs steam onto the turbine blades.

- Rotor: This part contains the blades that spin when steam flows over them.

- Reheating system: Some steam turbines utilize a reheating system for increased efficiency.

3.2 Applications of Steam Turbines

These turbines serve several important functions in various industries, including:

- Electric power generation

- Marine propulsion

- Mechanical drive in manufacturing processes

Consequently, their importance cannot be overstated.

4. Steam Turbine Design and Usage

Understanding the design and operation of steam turbines provides insights into their efficiency and performance. Various design configurations exist, including:

- Impulse Turbines: These turbines convert steam’s energy by jets, creating impulse forces that spin the rotor.

- Reaction Turbines: These turbines use both the steam pressure and the steam’s movement, offering higher efficiencies.

No matter the design, steam turbines inherently contribute to energy production, supporting the operational needs of countless businesses.

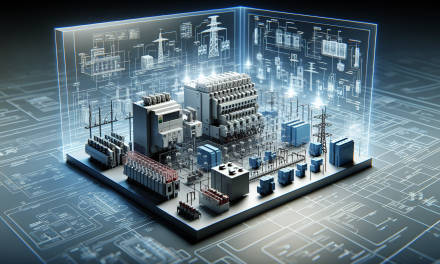

5. Energy Efficiency Optimization

Energy efficiency is a pivotal aspect of modern engineering. By optimizing centrifugal compressors and steam turbines, significant energy savings can be achieved. Some strategies include:

- Regular maintenance and calibration of equipment

- Implementing automation technology to monitor and control operations efficiently

- Utilizing waste heat recovery systems to enhance overall efficiency

These practices not only lower costs but also reduce environmental impact, aligning with global sustainability goals.

6. Benefits of Certification

Obtaining a certification in centrifugal compressors and steam turbines can be a game-changer for professionals seeking career advancement. A program like the Centrifugal Compressor & Steam Turbine Certification Course equips individuals with essential skills and knowledge. Some benefits of certification include:

- Enhancing employability with proven expertise

- Improving potential for higher salaries

- Gaining recognition as a knowledgeable professional in the field

- Networking opportunities with industry experts and peers

Such certifications often lead to increased responsibilities and better positions within organizations.

7. Frequently Asked Questions

7.1 What is the role of a centrifugal compressor?

A centrifugal compressor is primarily responsible for increasing the pressure of a gas, making it essential for various applications such as air conditioning, gas transportation, and process industries.

7.2 How does a steam turbine generate electricity?

A steam turbine generates electricity by harnessing the thermal energy from steam, which rotates the turbine blades and converts this energy into mechanical energy, ultimately driving a generator.

7.3 What are the benefits of obtaining certification in these areas?

Certifications demonstrate a professional’s competency in centrifugal compressors and steam turbines, enhancing career prospects and opening doors to new opportunities.

7.4 Are there other resources for further learning?

Absolutely! You can explore various topics related to industrial efficiency and optimization through resources such as:

- Mastering Cooling Towers: Essential Insights

- Understanding Reliability and Performance

- Unlocking Energy Efficiency

- Unleashing Professional Potential

- Unlocking the Power of Renewable Energy

8. Conclusion

In conclusion, mastering the principles of centrifugal compressors and steam turbines can significantly impact efficiency and sustainability in industrial applications. Whether working in power generation or manufacturing, understanding these machines is vital for driving success in engineering careers. By pursuing professional certifications, individuals further distinguish themselves in a competitive job market, opening avenues for continuous growth and learning in this essential field.