Table of Contents

- Introduction

- The Importance of Piping Systems Optimization

- Techniques for Optimizing Piping Systems

- Choosing the Right Materials and Components

- Mastering Fluid Flow Control Systems

- Understanding Fluid Machinery

- The Art of Solid Transport

- Navigating Challenges in Offshore Oil & Gas Industries

- Enhancing Resilience in Process Equipment

- FAQs

- Conclusion

Introduction

In today’s rapidly evolving industrial landscape, ensuring the efficiency of piping systems emerges as a priority for professionals in the oil and gas sector. Properly optimized piping networks can lead to significant energy savings, reduced operational costs, and enhanced safety. This article explores how professionals can enhance their understanding of piping systems and drive optimization efforts, supported by practical insights and useful resources.

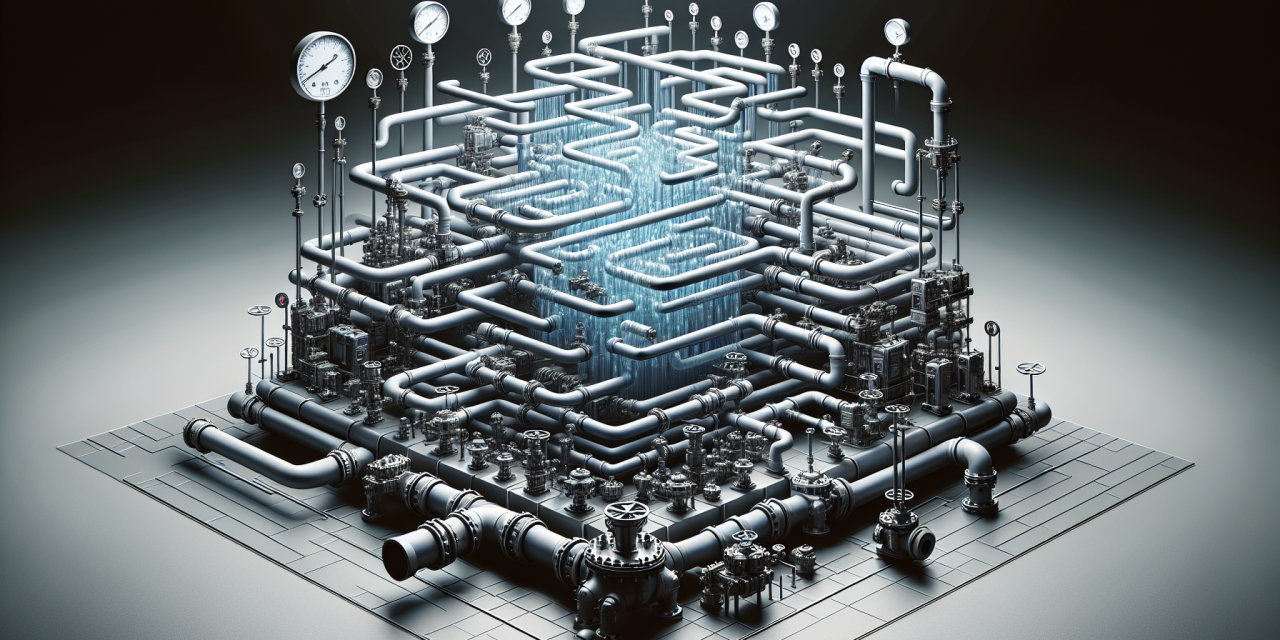

The Importance of Piping Systems Optimization

Optimizing piping systems plays a critical role in various industrial operations, especially in oil and gas. Effective pipeline design and management not only improve fluid transport efficiency but also prevent system failures. Furthermore, optimizing these systems results in lower emissions and sustainable operations. Aside from direct benefits, improved piping systems also contribute to compliance with industry regulations and standards, which is crucial for operational continuity and reputation.

Why Focus on Optimization?

The pursuit of optimization should center around several compelling reasons. Firstly, optimized systems enhance energy efficiency, which translates to significant cost savings. Moreover, understanding the fundamentals of optimization helps in identifying bottlenecks and potential failures before they escalate into costly incidents. By pursuing this knowledge, professionals increase not only their technical skills but also their value within their organizations.

Techniques for Optimizing Piping Systems

Professionals aiming for effective piping systems optimization should employ several techniques. Here’s a look at some of the most effective strategies:

1. Employing Computational Fluid Dynamics (CFD)

The use of CFD software opens doors to simulations that reveal how fluids behave within a piping system. By employing CFD, one can visualize flow pattern changes, pressure drops, and potential leakage points, enabling proactive adjustments to design and operational practices.

2. Regular Maintenance and Monitoring

A consistent maintenance schedule enhances the longevity and performance of piping systems. Integrating modern monitoring tools facilitates real-time analysis of flow rates, pressures, and temperatures, allowing for timely interventions.

3. Implementing Energy Recovery Systems

Integrating energy recovery systems can lead to significant energy savings. These systems collect waste energy and redirect it back into the piping process, reducing overall consumption.

Choosing the Right Materials and Components

The choice of materials and components directly affects the efficiency of a piping system. Certain materials offer better corrosion resistance, while others may withstand higher pressures.

Material Properties and Their Impact

Understanding material properties, such as tensile strength, fatigue resistance, and thermal expansion coefficients, empowers professionals to make informed decisions. For further reading, consider exploring Navigating the Complexities: Materials and Welding Challenges in Offshore Oil & Gas Industries, which provides insights into material choices in more demanding environments.

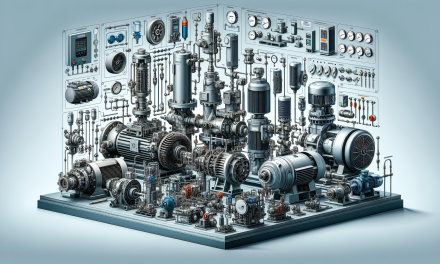

Mastering Fluid Flow Control Systems

Effective control of fluid flow is a cornerstone of system efficiency. By mastering fluid control principles, one can significantly enhance overall piping performance. Various valves, pumps, and controllers facilitate optimal flow.

The Role of Valve Selection

Selecting the right valve for the application can minimize pressure losses and prevent turbulence. Explore more about fluid flow control in Mastering Fluid Flow Control Systems: A Key Element in Process Industry Efficiency for deeper insights.

Understanding Fluid Machinery

Proficient operation and maintenance of pumps, compressors, and turbines ensure a seamless piping system. Gaining an understanding of the operational principles behind these machines is invaluable. Consider reading Understanding Fluid Machinery: Mastering Operation and Maintenance of Pumps, Compressors, and Turbines to delve into this area further.

The Art of Solid Transport

For processes involving the transport of solids, effective conveying systems are crucial. Mastering hydraulic and pneumatic conveying techniques can drive optimization in various industries. For comprehensive guidance, refer to The Art of Solid Transport: A Comprehensive Guide to Hydraulic and Pneumatic Conveying Systems.

Navigating Challenges in Offshore Oil & Gas Industries

Offshore operations present unique challenges, including harsh environmental conditions and complex logistics. Addressing these challenges requires specialized knowledge and advanced strategies. By exploring Navigating the Complexities: Materials and Welding Challenges in Offshore Oil & Gas Industries, professionals can gain insights into overcoming these obstacles effectively.

Enhancing Resilience in Process Equipment

Building resilience in process equipment and piping systems involves tackling failures and implementing prevention strategies. Regular evaluations and emergency response plans are essential to mitigating risks. Explore the methods for improving resilience in Enhancing Resilience in Process Equipment and Piping.

FAQs

What are the key benefits of optimizing piping systems?

Optimizing piping systems leads to improved energy efficiency, reduced operational costs, enhanced safety, and compliance with industry standards. Furthermore, it can prevent costly downtime and increase the system’s overall lifespan.

How can professionals stay updated with the latest techniques in piping optimization?

Engaging with industry literature, attending relevant workshops, and participating in specialized learning events can help professionals stay abreast of the latest techniques and innovations in piping systems optimization. An excellent resource is Piping Systems Optimization Training for Oil & Gas Professionals, which provides valuable insights and practical methods to enhance expertise.

What are some common mistakes to avoid in piping system maintenance?

Common mistakes include neglecting regular inspections, failing to replace worn components in a timely manner, and not adequately training staff on operational practices. To avoid these missteps, it is vital to adopt a proactive approach to both maintenance and training.

Conclusion

In summary, optimizing pipes and piping systems significantly enhances efficiency in the oil and gas sector. By employing various strategies, understanding material properties, mastering fluid dynamics, and navigating industry challenges, professionals can drive both personal and organizational success. As the industry continues to evolve, investing in knowledge and training, such as the resource mentioned above, becomes paramount for staying competitive and ensuring safe, efficient operations.