Table of Contents

- Introduction

- What is Industrial Instrumentation?

- Importance of Industrial Instrumentation

- Modern Control Systems

- Impact of Modern Control Systems on Industrial Processes

- Integration of Industrial Instrumentation and Control Systems

- Training and Development in Industrial Instrumentation

- Challenges in Instrumentation and Control Systems

- FAQs

- Conclusion

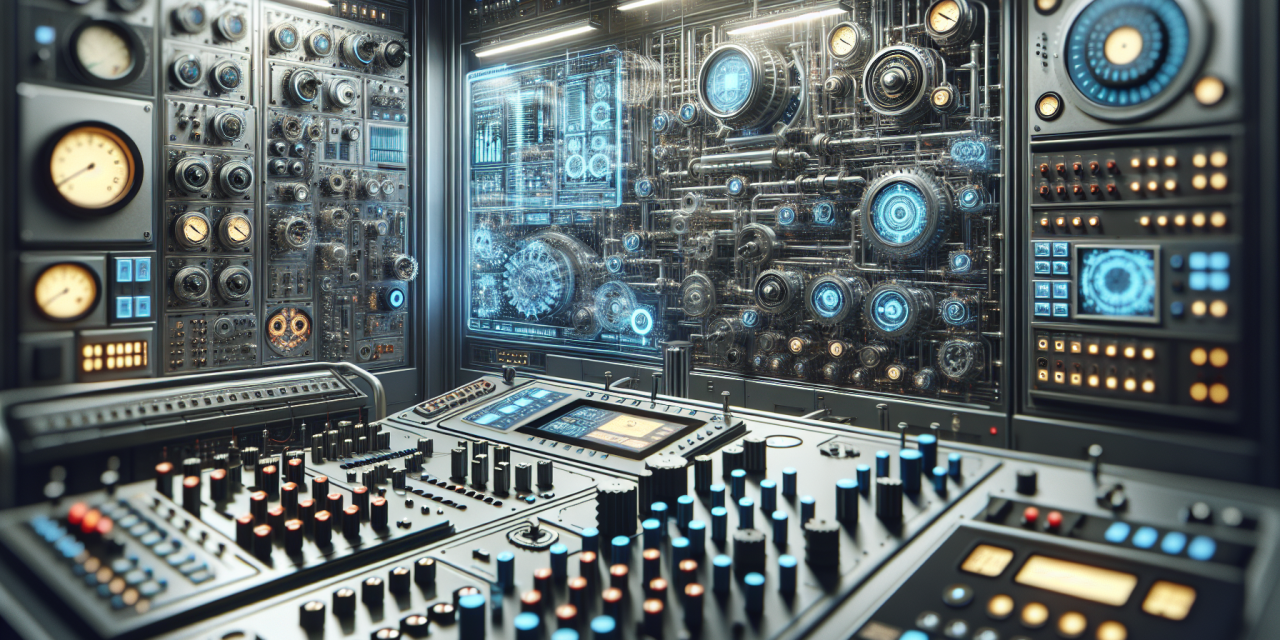

Introduction

In today’s fast-paced industrial landscape, the significance of industrial instrumentation and modern control systems cannot be overstated. Industries across various sectors rely on these technologies to enhance productivity, ensure safety, and improve the quality of their products. As we delve into this topic, we will uncover the vital components and benefits of industrial instrumentation and how modern control systems play a crucial role in the operational framework of industrial processes.

What is Industrial Instrumentation?

Industrial instrumentation involves the use of various devices to measure, control, and analyze different parameters of industrial processes. This encompasses a wide range of instruments, including sensors, transmitters, controllers, and actuators. Essentially, it forms the backbone of automation in industries, enabling accurate monitoring and control of processes.

The Components of Industrial Instrumentation

The components often found in industrial instrumentation systems include:

- Sensors: These devices measure physical variables such as pressure, temperature, flow, and level. For instance, thermocouples measure temperature by producing a voltage corresponding to temperature changes.

- Transmitters: After the sensors gather data, transmitters convert this data into a signal that can be easily interpreted by control systems. This ensures seamless communication between the measurement point and the controller.

- Controllers: These devices receive input from transmitters and make decisions or adjustments to maintain desired process parameters. They play a pivotal role in ensuring that processes remain within safe and efficient thresholds.

- Actuators: Actuators convert control signals from controllers into physical actions, such as opening a valve or adjusting a pump speed, thereby directly influencing the industrial process.

Importance of Industrial Instrumentation

Understanding the importance of industrial instrumentation goes hand in hand with recognizing its benefits:

- Enhanced Efficiency: By automating measurement and control processes, industries can achieve higher levels of efficiency. For example, consistent flow measurement allows for the precise formulation of products, significantly reducing wastage.

- Increased Safety: Safety is paramount in industrial operations. Instruments detect hazardous conditions and triggers appropriate safety measures. Modern instrumentation helps prevent accidents and protects the workforce.

- Better Data Collection: The integration of advanced instrumentation allows for the real-time collection of data, which is crucial for making informed decisions. Companies can analyze trends and make proactive adjustments to processes.

- Cost-effectiveness: Over time, the implementation of industrial instrumentation leads to lower operational costs. Although there may be initial investments, reduced labor costs and increased productivity typically compensate for this.

Modern Control Systems

Modern control systems have evolved from traditional approaches to offer intricate solutions for managing industrial processes. These advanced systems utilize technology, including software and algorithms, to ensure processes run smoothly.

Types of Modern Control Systems

Understanding different types of modern control systems enables industries to select the most suitable one for their needs:

- Distributed Control Systems (DCS): These systems distribute control functions across various locations. This centralizes the monitoring of an entire process while allowing for localized decision-making.

- Programmable Logic Controllers (PLC): PLCs are essential for automating electromechanical processes. They offer flexibility by allowing users to program specific instructions for various control actions.

- Supervisory Control and Data Acquisition (SCADA): SCADA systems monitor and control industrial processes at a high level. They gather real-time data and display critical information to operators, facilitating optimal decision-making.

Impact of Modern Control Systems on Industrial Processes

Modern control systems have transformed how industries operate. The impact can be seen in several areas:

- Real-time Monitoring: The rise of real-time monitoring allows industries to respond immediately to changes in process conditions, significantly reducing the likelihood of errors.

- Improved Productivity: Automation through modern control systems leads to streamlined operations, reducing downtime and boosting overall productivity.

- Data Analytics: With advanced control systems, industries can analyze large amounts of data efficiently. By utilizing this analytics, companies can optimize their processes, identify bottlenecks, and improve overall performance.

- Enhanced Compliance: Many industries face stringent regulations. Modern control systems help ensure compliance by providing accurate data and documentation required for audits and inspections.

Integration of Industrial Instrumentation and Control Systems

Integrating industrial instrumentation with modern control systems is essential for achieving maximum efficiency. By doing so, industries can create a cohesive environment that enhances functionality.

The Benefits of Integration

- Simplified Operations: Integration simplifies operations by streamlining the communication between various devices. When instruments communicate effectively with control systems, it reduces the chances of manual errors.

- Boosted Reliability: An integrated system tends to be more reliable as it operates cohesively. This means fewer breakdowns or inaccuracies in monitoring, enhancing overall system reliability.

- Holistic View of Operations: With integrated systems, operators have a complete view of operations in real time. This comprehensive perspective allows for better decision-making and quicker responses to any issues.

Training and Development in Industrial Instrumentation

With the rapid evolution of industrial instrumentation and control systems, ongoing training and development become increasingly critical. Professionals must stay updated with the latest technologies and methodologies.

For those looking to enhance their knowledge in this area, consider exploring the Industrial Instrumentation & Control Systems Course Training. This training empowers individuals with the necessary skills to navigate the complexities of modern industrial processes.

Challenges in Instrumentation and Control Systems

Despite the many advancements and benefits of industrial instrumentation and control systems, industries face several challenges:

- Technological Complexity: As technologies evolve, keeping up with the latest advancements can overwhelm many professionals. Continuous learning is essential, yet time-consuming.

- Integration Issues: Merging legacy systems with modern technologies can pose challenges. Industries must carefully plan their integration strategies to avoid disruptions.

- Maintenance Requirements: Maintenance of instrumentation and control systems requires skilled personnel. Finding employees with the necessary expertise can sometimes be a challenge.

FAQs

What industries utilize industrial instrumentation and control systems?

Many industries, including oil and gas, manufacturing, pharmaceuticals, and water treatment, rely on industrial instrumentation and control systems to optimize their processes.

How do industrial instrumentation systems enhance safety?

Industrial instrumentation systems enhance safety by continuously monitoring critical parameters, allowing for rapid responses to any anomalies that could pose safety risks.

Are there specific certifications available for professionals in this field?

Yes, there are various certifications and training programs focused on industrial instrumentation and control systems. These programs help professionals gain the necessary skills and knowledge to succeed.

How can integration affect overall productivity?

Integration fosters seamless communication between devices, reducing errors and downtime, and ultimately leading to increased overall productivity.

Conclusion

In conclusion, industrial instrumentation and modern control systems are indispensable in today’s industries. They not only streamline processes but also enhance safety and efficiency. As industries continue to evolve, being knowledgeable about these systems will play a crucial role in sustaining competitive advantages. For those eager to delve deeper into this realm, numerous resources and training opportunities are available, ensuring that professionals remain equipped to meet the demands of an ever-changing industrial landscape. In addition, for relevant insights into industry project management and risk strategies in the oil and gas sector, explore the following resources:

- Effective Risk Management Strategies for Oil & Gas Projects

- Comprehensive Financing Solutions for Oil & Gas Mining Projects

- Unlocking Success: The Essential Guide to Oil and Gas Project Management

- Mastering Project Management in the Oil and Gas Industry: A Comprehensive Guide

- Mastering Oil & Gas Accounting: Unlocking Performance Metrics for Success

By embracing the advancements in instrumentation and control systems, industries can pave the way for a smarter and more efficient future.