Table of Contents

- Introduction

- Power Generation Methods

- Advantages and Disadvantages

- The Future of Power Generation

- FAQs

- Conclusion

Introduction

Power generation is a crucial aspect of modern society, providing the electricity necessary for homes, businesses, and industries. To meet rising demand, engineers and scientists have developed various methods of power generation, including steam turbines, gas turbines, and combined cycle power plants. In this article, we will dive into each of these methods, examining their mechanisms, advantages, and disadvantages.

Power Generation Methods

Power generation methods each have unique processes and technologies. Understanding these differences can help in choosing the appropriate method for specific applications.

Steam Turbines

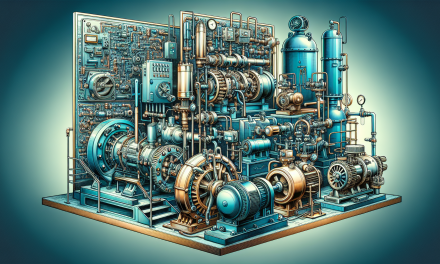

Steam turbines utilize steam produced from boiling water to generate electricity. In this process, water is heated in a boiler, producing high-pressure steam that expands and spins the blades of a turbine connected to a generator. This method of power generation has been in use for over a century and continues to be widely adopted in various power plants.

How Steam Turbines Work

The operation of steam turbines involves several steps: First, water is heated to produce steam under pressure. Then, the steam flows through a turbine, which rotates it. Finally, this rotation drives a generator to produce electricity.

Advantages of Steam Turbines

- High efficiency when used with large power plants.

- Ability to use a variety of fuels, including fossil fuels, nuclear, and renewable sources like biomass.

- Established technology with a vast network of existing plants.

Disadvantages of Steam Turbines

- High initial investment costs due to infrastructure and equipment.

- Requires a significant amount of water for steam generation.

- Long start-up times compared to gas turbines.

Gas Turbines

Gas turbines operate on a different principle than steam turbines. Instead of steam, gas turbines use combustion to generate hot gases that spin the blades of a turbine. This makes gas turbines particularly suitable for quick respond to changes in electricity demand.

How Gas Turbines Work

In a gas turbine, air is compressed before fuel is injected and ignited. The resulting combustion generates high-pressure gas that drives the turbine. After passing through the turbine, the gases are expelled at high speed, ensuring that the turbine stays in motion.

Advantages of Gas Turbines

- Quick start-up and shut-down capabilities, making them ideal for peak load electricity generation.

- Smaller footprint compared to steam turbines, allowing for flexible installation.

- Lower emissions when using natural gas compared to traditional coal-fired plants.

Disadvantages of Gas Turbines

- Generally lower efficiency than steam turbines in large-scale applications.

- Fuel costs can vary significantly, impacting operational costs.

- Reliant on the availability of natural gas, which can be a limitation in remote areas.

Combined Cycle Power Plants

Combined cycle power plants integrate both steam and gas turbines to achieve enhanced efficiency. The waste heat from the gas turbine is used to generate steam, which drives a steam turbine. This synergy maximizes energy extraction from the fuel used.

How Combined Cycle Power Plants Work

In a combined cycle system, the gas turbine generates electricity and hot exhaust gases. Devices called heat recovery steam generators (HRSG) capture this exhaust heat, converting it into steam that powers a steam turbine. This configuration effectively improves the overall efficiency of the power plant, often exceeding 60%.

Advantages of Combined Cycle Power Plants

- Higher efficiency rates compared to standalone gas or steam turbine systems.

- Flexibility in fuel use and operational modes.

- Lower overall emissions due to improved fuel utilization.

Disadvantages of Combined Cycle Power Plants

- Higher complexity in design and operation compared to single-cycle plants.

- Can be more expensive to build and maintain due to integrated systems.

- Requires significant planning for infrastructure and fuel supply.

Advantages and Disadvantages Summary

Choosing a particular method of power generation depends on various factors, including cost, environmental considerations, and operational efficiency. While steam turbines are beneficial for large-scale projects, gas turbines offer flexibility and quick response times. Combined cycle systems aim to leverage the advantages of both types, delivering efficiency and reduced emissions.

The Future of Power Generation

As we look towards the future of power generation, trends indicate an increasing focus on sustainability and renewable energy sources. Innovations in technology are leading to more efficient and environmentally friendly methods, such as integrating solar and wind energy with existing systems like gas and steam turbines.

Moreover, enhanced training programs and resources in power generation can be invaluable for professionals in the industry. For those interested in expanding their knowledge, check out Power Generation Training: Steam & Gas Turbines, Combined Cycle. This program offers insights into cutting-edge techniques necessary for thriving in the power generation field.

FAQs

What are the main differences between steam turbines and gas turbines?

Steam turbines utilize steam produced by boiling water, whereas gas turbines rely on combustion gases. Steam turbines are typically more efficient for large plants, while gas turbines can start and stop quickly and operate effectively at smaller scales.

How do combined cycle power plants enhance efficiency?

Combined cycle power plants utilize the waste heat from gas turbines to produce steam, which powers steam turbines. This dual-use approach maximizes energy extraction from the fuel, significantly increasing overall efficiency compared to using either turbine type alone.

What are some trends in the power generation industry?

There is a growing trend toward integrating renewable energy sources, such as solar and wind, into existing power generation frameworks. Additionally, advancements in technology and increased emphasis on reducing emissions are influencing future designs and operations.

Where can I learn more about optimizing refinery processes?

To learn about maximizing efficiency in refinery processes, you can visit Maximizing Efficiency in Refinery Processes. This resource discusses techniques that can help improve yield optimization and overall operational efficiency.

What resources are available for those entering the petroleum industry?

If you’re considering a career in the petroleum industry, you might find value in a deep dive into training programs that cover essential strategies for production planning and scheduling.

Conclusion

In conclusion, power generation is a complex but essential aspect of modern life. Understanding the different methods, including steam turbines, gas turbines, and combined cycle power plants, allows us to make informed decisions regarding energy production. With ongoing technological innovations and a push toward sustainable energy, the future of power generation looks promising and vital for both industry and the environment.