Table of Contents

- 1. Introduction

- 2. What is Fluid Machinery?

- 3. Types of Fluid Machinery

- 4. Operation and Maintenance

- 5. Best Practices in Maintaining Fluid Machinery

- 6. Challenges in Fluid Machinery Operation

- 7. Conclusion

- 8. FAQs

1. Introduction

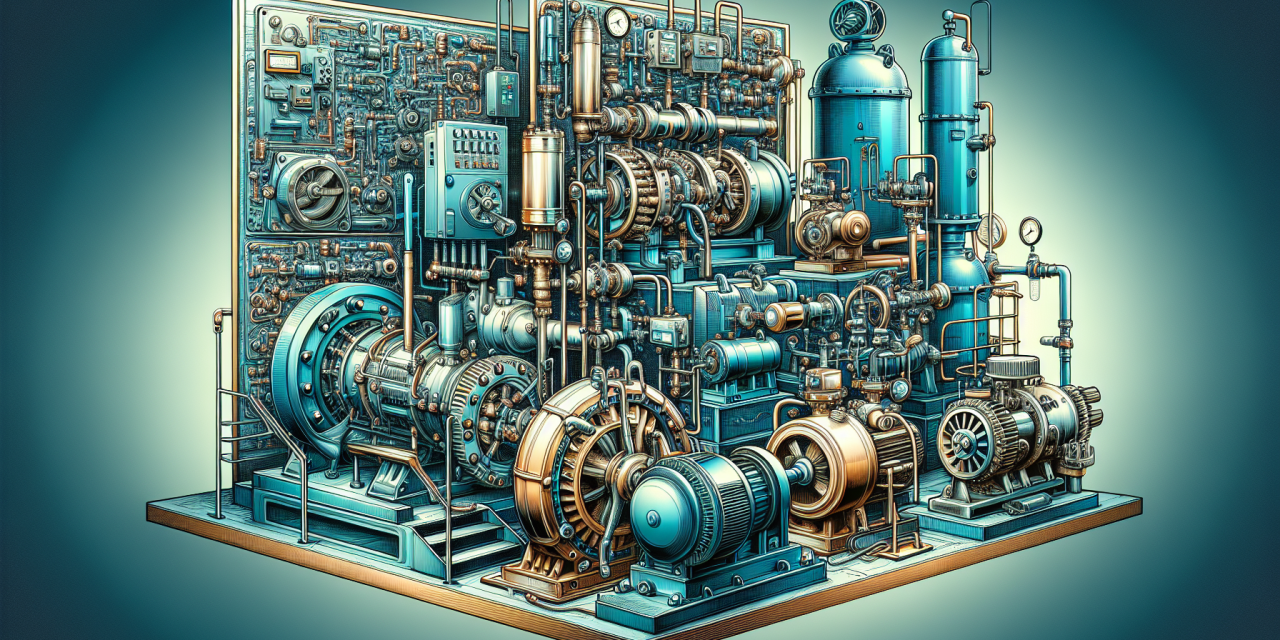

Fluid machinery plays a crucial role in our industrial landscape. From pumping liquids to compressing gases and generating power, these machines are pivotal in various sectors, including oil and gas, manufacturing, and water treatment. As technology evolves, so do the demands for efficiency, reliability, and performance in fluid machinery systems. In this blog post, we will delve into the operation and maintenance of pumps, compressors, and turbines, providing you with valuable insights that can enhance your understanding and application of these machines.

2. What is Fluid Machinery?

Fluid machinery encompasses a wide range of equipment that utilizes fluids (liquids and gases) to transfer energy. Essentially, these machines either convert energy into fluid motion or harness fluid motion to generate energy. This dynamic relationship is vital for numerous applications, making fluid machinery a central topic in engineering and maintenance fields.

3. Types of Fluid Machinery

Fluid machinery generally falls into three fundamental categories: pumps, compressors, and turbines. Each type has unique characteristics and applications that make them suitable for different scenarios.

3.1 Pumps

Pumps are primarily used to move liquids. They work by creating a pressure differential that pushes fluid from one location to another. Various types of pumps exist, including:

- Positive Displacement Pumps

- Centrifugal Pumps

- Diaphragm Pumps

- Submersible Pumps

Understanding the specific requirements of your application will help you select the right pump type.

3.2 Compressors

Compressors serve as essential equipment for converting energy into potential energy stored in gas. They work by reducing the volume of gas, thereby increasing its pressure. Some common types of compressors include:

- Reciprocating Compressors

- Rotary Screw Compressors

- Centrifugal Compressors

Choosing the correct compressor can significantly influence efficiency and performance in operations where gas compression is necessary.

3.3 Turbines

Turbines are devices that convert fluid energy into mechanical energy. They are commonly employed in power generation and propulsion applications. Key types of turbines include:

- Steam Turbines

- Gas Turbines

- Hydraulic Turbines

Understanding the operational principles and applications of turbines will help in maximizing their effectiveness.

4. Operation and Maintenance

Successful operation and maintenance of fluid machinery require a combination of technical knowledge, skills, and diligent practices.

4.1 Operation of Fluid Machinery

Operating fluid machinery involves understanding its fundamental principles and following best practices. Some key aspects to consider include:

- Understanding Operational Parameters: It’s crucial to know the specifications, such as flow rates, pressures, and temperatures.

- Monitoring Performance: Regularly checking the operation can identify potential issues before they escalate.

- Safety Protocols: Ensuring safety measures are in place protects personnel and equipment.

These operational aspects significantly contribute to your machinery’s longevity and effectiveness.

4.2 Maintenance Practices

Appropriate maintenance practices are essential to prevent unexpected failures and ensure consistent performance. Strategies may include:

- Regular Inspections: Scheduled inspections can significantly reduce the risk of failures.

- Lubrication: Proper lubrication minimizes wear and reduces the chances of malfunction.

- Calibration: Regular calibration of machinery ensures accuracy and consistent performance.

Implementing these practices enhances the longevity of your equipment.

5. Best Practices in Maintaining Fluid Machinery

To boost the performance and reliability of fluid machinery, adhere to these best practices:

- Implement Predictive Maintenance: Utilize modern technology to anticipate failures and schedule maintenance proactively.

- Document All Maintenance Activities: Keeping detailed records enhances accountability and helps track performance trends.

- Invest in Training: Considering enrolling in a comprehensive training program can enhance staff skills and knowledge. For instance, you can explore the Fluid Machinery Course: Operation & Maintenance of Pumps & Turbines to gain deeper insights.

By adopting these practices, you can ensure your fluid machinery operates at its best.

6. Challenges in Fluid Machinery Operation

Despite advancements in technology, operators still face challenges when managing fluid machinery.

- Wear and Tear: Regular operation leads to parts, especially seals and bearings, wearing out over time.

- Operational Efficiency: Achieving optimal efficiency can sometimes be hampered by external variables.

- Human Error: Lack of knowledge or experience can lead to mistakes during operation or maintenance processes.

Addressing these challenges requires ongoing training and adherence to best practices, leading to better outcomes.

7. FAQs

What are the main differences between pumps, compressors, and turbines?

Pumps generally move liquids, compressors deal with gases, and turbines convert the energy found in fluids into mechanical work. Each has unique operational characteristics and applications.

How can I improve the efficiency of my fluid machinery?

Improving efficiency can be achieved through regular maintenance, performance monitoring, and implementing best practices in operation. Training staff can also yield significant improvements.

Where can I find more resources for further understanding fluid machinery?

There are various resources available online; forums, blogs, and specialized training programs, such as the Fluid Machinery Course: Operation & Maintenance of Pumps & Turbines, offer in-depth knowledge.

What are the common failures in each type of fluid machinery?

Common failures vary; pumps often suffer from seal leaks, compressors can encounter pressure losses, and turbines may face blade erosion. Regular maintenance can help mitigate these issues.

8. Conclusion

Fluid machinery operations are complex, requiring a combination of technical knowledge and practical skills to ensure effective functionality. By understanding the specific characteristics of pumps, compressors, and turbines and adhering to best practices, you can significantly enhance the operation and longevity of your equipment. Remember, staying proactive in maintenance and improvements leads to a successful partnership with your fluid machinery. Furthermore, you can also access valuable content related to hydraulic and pneumatic systems at Mastering the Art of Solid Transport and other specialized blogs that tackle challenges in offshore and process equipment maintenance. Consistent education is key to mastering these vital components of our industrial world.