Table of Contents

- Introduction

- Importance of Offshore Pipelines

- Key Aspects of Pipeline Design

- Installing Offshore Pipelines

- Maintenance Challenges

- Essential Technical Skills

- Adhering to Industry Standards

- Future Trends in Offshore Pipeline Engineering

- FAQs

- Conclusion

Introduction

Offshore pipeline engineering plays a crucial role in the energy industry, facilitating the transportation of oil and gas from production fields to processing facilities. Understanding the fundamentals of this field is essential for professionals aiming to excel in various roles related to energy and environmental engineering. In this article, we will explore the critical elements of offshore pipeline engineering, from design to maintenance, as well as the skills necessary for success in this dynamic field.

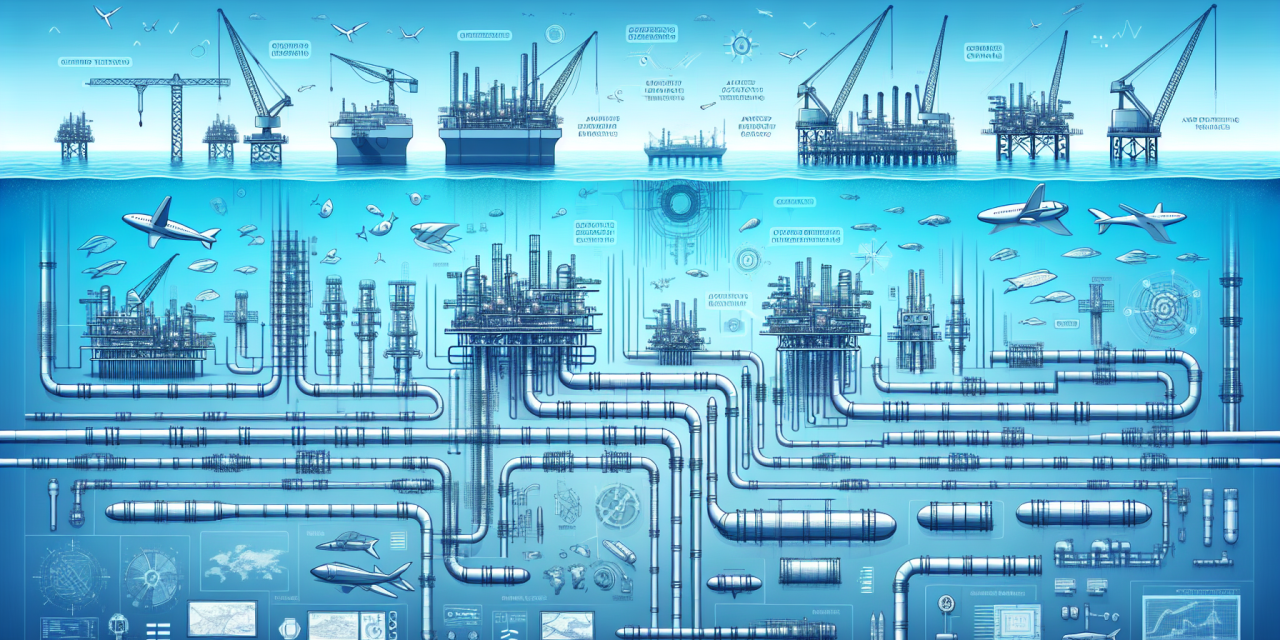

Importance of Offshore Pipelines

As the global demand for energy continues to surge, ensuring efficient methods of transporting hydrocarbons becomes increasingly important. Offshore pipelines are vital for:

- Carrying oil and gas from undersea reservoirs.

- Increasing the efficiency of energy production.

- Minimizing environmental risks through advanced technologies.

Moreover, offshore pipelines contribute significantly to global energy security. As such, they represent immense engineering challenges that require knowledge, skills, and innovative solutions.

Key Aspects of Pipeline Design

A well-designed offshore pipeline must account for various factors, including:

Hydrodynamic Forces

When designing pipelines, engineers must consider the hydrodynamic forces acting on submerged structures. These forces may include currents, wave actions, and turbulence. Careful calculations ensure that pipelines can withstand potential environmental stressors.

Material Selection

Choosing appropriate materials is essential for the longevity and success of offshore pipelines. The chosen materials must resist corrosion, withstand pressure, and endure extreme temperatures. Common materials used in pipeline construction include:

- Carbon steel

- Stainless steel

- High-density polyethylene (HDPE)

Every material has its strengths and weaknesses, which must align with the specific challenges presented by the offshore environment.

Geotechnical Considerations

The seabed’s geological characteristics significantly influence design. Engineers must assess soil types, fault lines, and sediment dynamics. Gathering geotechnical data helps establish safe pipeline routes and reliable anchoring solutions.

Regulatory Compliance

Ensuring compliance with local and international regulations is critical during the design phase. Regulatory bodies establish guidelines to minimize environmental impacts and ensure safety. Resources such as the Offshore Pipeline Engineering, Design, & Installation Course provide valuable insights into navigating these regulatory landscapes.

Installing Offshore Pipelines

Pipeline installation represents a complex process requiring meticulous planning and execution. In this phase, engineers will face various challenges, including:

Installation Methods

There are several methods for installing offshore pipelines, including:

- Lay barge techniques

- Saturation diving

- Remote-operated vehicles (ROVs)

Each of these methods has unique advantages and challenges, and the choice depends on project specifications, site conditions, and environmental factors.

Safety Protocols

Implementing safety protocols is indispensable during the installation process. Engineers and technicians must prioritize health and safety management systems to protect workers and the surrounding environment. This includes conducting risk assessments and emergency response planning.

Maintenance Challenges

Once installed, offshore pipelines require ongoing maintenance to ensure operational efficiency and safety. Key maintenance challenges include:

Corrosion Control

Corrosion poses a significant threat to the integrity of offshore pipelines. Implementing corrosion prevention strategies is fundamental. These strategies may involve applying coatings, utilizing cathodic protection, and conducting regular inspections.

Leak Detection

Early detection of leaks is essential in preventing environmental contamination and economic loss. Various technologies can assist in leak detection, including:

- Acoustic monitoring

- Pressure monitoring

- Smart pigging

Employing a combination of these methods enhances the reliability of the monitoring system.

Essential Technical Skills

Excelling in offshore pipeline engineering requires a combination of technical knowledge and practical skills. Essential skills include:

Analytical Skills

Effective problem-solving and analytical abilities enable engineers to evaluate designs, interpret data, and make informed decisions.

Project Management

Strong project management capabilities are paramount in ensuring that projects are completed on time and within budget. This includes planning, resource allocation, and stakeholder communication.

Interdisciplinary Collaboration

Offshore pipeline engineering often involves collaboration across various disciplines—such as mechanical, civil, and environmental engineering. Professionals must possess the ability to work cohesively within multidisciplinary teams.

Adhering to Industry Standards

Familiarizing oneself with industry standards is critical. Awareness of reputable guidelines such as ASME B31.3 for process piping design helps engineers produce safe, efficient, and compliant designs. Resources to learn more about these standards include Mastering the ASME B31.3 Process Piping Design Code: What You Need to Know.

Moreover, understanding the regulatory landscape can significantly impact project success. Information on international petroleum management is crucial, especially in oil and gas operations, as discussed in this Comprehensive Guide to International Petroleum Management in Oil and Gas Operations.

Future Trends in Offshore Pipeline Engineering

The offshore pipeline industry continually evolves, influenced by technological advancements and sustainability initiatives. Key trends include:

Smart Technologies

The integration of smart technologies, such as IoT sensors and real-time monitoring systems, is becoming increasingly common. These technologies enhance the way engineers manage pipeline integrity and performance.

Sustainable Practices

Promoting sustainability within pipeline engineering is more important than ever. Engineers are exploring innovative designs and materials that minimize environmental impacts while enhancing energy efficiency. For insights into managing waste in petrochemical industries, visit Mastering Wastewater Management in the Oil Refinery and Petrochemical Industries.

FAQs

What is the role of offshore pipelines in the energy industry?

Offshore pipelines transport hydrocarbons from production sites to processing facilities, ensuring a continuous supply of energy resources.

What materials are commonly used in offshore pipeline construction?

Common materials include carbon steel, stainless steel, and high-density polyethylene (HDPE), each chosen for its specific strengths in the offshore environment.

What are the main challenges faced during pipeline installation?

Challenges include selecting appropriate installation methods, ensuring worker safety, and adhering to environmental regulations.

Conclusion

The field of offshore pipeline engineering embodies a blend of technical expertise and innovative thinking. From understanding key design principles to mastering installation and maintenance processes, the journey is continuous and rewarding. As industry professionals take on these challenges, they not only contribute to energy production but also play a vital role in protecting our environment. For those looking to delve deeper into offshore pipeline engineering, consider exploring resources like the Offshore Pipeline Engineering, Design, & Installation Course. Engaging with ongoing learning can only enhance one’s career in this exciting sector.