Table of Contents

- Introduction

- Understanding LNG Bunkering

- Importance of LNG Fuel Management

- Strategies for Effective Bunkering

- Safety Protocols in LNG Bunkering

- Technological Advancements in LNG Management

- Best Practices for LNG Fuel Optimization

- Industry Insights

- FAQs

- Conclusion

Introduction

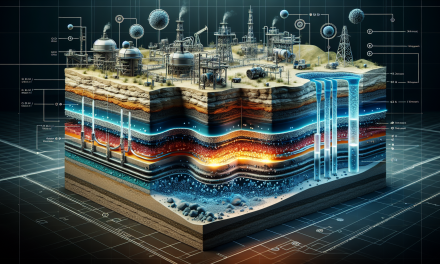

Liquid Natural Gas (LNG) has transformed the maritime fuel landscape. It not only offers a cleaner alternative to traditional marine fuels but also complies with stringent environmental regulations. As the shipping industry pivots toward greener solutions, understanding the nuances of managing LNG bunkering and fuel use is vital.

Understanding LNG Bunkering

LNG bunkering refers to the process of supplying LNG fuel to ships. To comprehend this process, it’s essential to familiarize oneself with the facilities and methodologies involved in bunkering. Of course, successful bunkering requires collaboration among various stakeholders, including shipowners, port authorities, and fuel suppliers.

Key Terminologies in LNG Bunkering

To navigate the world of LNG, here are some key terms to know:

- Bunkering: The act of fueling a ship.

- Transshipment: The transfer of cargo from one vessel to another.

- Regasification: Converting LNG back into gas.

- Cold Ironing: Using shore-based energy to power ships at berth.

Importance of LNG Fuel Management

Effectively managing LNG fuel on ships goes beyond just the bunkering process. Here, we’ll explore why it matters significantly:

- Environmental Compliance: LNG has a lower carbon footprint, helping operators adhere to international emission standards.

- Cost Efficiency: LNG fuels can be more cost-effective than traditional marine fuels, lowering operational expenses long-term.

- Operational Reliability: Proper management ensures consistent and safe fuel supply, minimizing disruptions during voyages.

Strategies for Effective Bunkering

Creating an effective LNG bunkering strategy involves several components. Let’s dive into a few strategies that can enhance efficiency and safety:

1. Thorough Planning

Begin with meticulous planning. When embarking on an LNG bunkering operation, schedule assessments for weather conditions, fuel availability, and port operations. This planning phase sets the stage for seamless execution.

2. Training and Education

Investing in training personnel is absolutely essential. It helps the crew understand the processes involved in managing LNG and fosters compliance with safety protocols. Resources like the LNG Bunkering and Fuel Management for Ships Course can provide valuable insights for ship crew and managers.

3. Monitoring Systems

Implement advanced monitoring systems to effectively track and manage LNG fuel consumption. Using real-time data analytics aids in optimizing fuel usage, pinpointing inefficiencies, and controlling costs.

Safety Protocols in LNG Bunkering

When handling LNG, safety cannot be understated. To ensure safe operations, adhere to these protocols:

- Personal Protective Equipment (PPE): All personnel must wear appropriate PPE to protect against potential hazards.

- Emergency Response Plans: Every ship should have a robust emergency response plan, including drills to prepare for any unforeseen incidents.

- Regular Equipment Maintenance: Conduct routine checks and maintenance on bunkering equipment to prevent malfunctions.

Technological Advancements in LNG Management

With the advancement of technology, managing LNG on ships has become more efficient than ever. The use of automation and digital tools facilitates not only accurate measurement but also reduced human error during bunkering operations. Let’s look at some of these innovations:

1. Automation Processes

Automated systems reduce manual intervention during bunkering, promoting safety and efficiency. These systems provide real-time monitoring and control, thereby enhancing operational reliability.

2. Advanced Analytics

Employing big data analytics allows ship operators to identify trends in LNG consumption and optimize bunkering schedules. This data-driven approach makes it easier to make informed decisions regarding fuel management.

Best Practices for LNG Fuel Optimization

As with any operational procedure in the maritime industry, following best practices ensures optimal results. Key best practices around LNG fuel management include:

1. Consistent Record-Keeping

Document each LNG bunkering operation. This record-keeping not only assists in regulatory compliance but also aids in reviewing actions for future improvements.

2. Collaboration with Stakeholders

Engage with all parties involved in the LNG supply chain. Establishing open communication channels with suppliers and port authorities can lead to improvements in the overall bunkering process.

Industry Insights

It’s worth noting that the maritime industry continually adapts. Recommendations for those in the LNG bunkering space include:

- Stay updated on regulations concerning emissions. For example, laws that affect oil and gas exploration may influence LNG usage.

- Regularly assess corrosion control strategies to prevent potential leaks and ensure safety within the bunkering operation, as discussed in this article on corrosion control strategies.

- Understand oil and gas pipeline operations to effectively integrate them with LNG management protocols. Read more about it in this insightful resource on pipeline operations.

- Train staff on building inspections as an essential part of the bunkering process to ensure every operational space is up to code. For more information, explore building envelope inspections.

- Adopt troubleshooting techniques tailored to process plant operations that can be linked to efficient LNG management. You may find useful insights in this article about process plant troubleshooting.

- Recognize that maximizing efficiency in refinery operations is critical in optimizing LNG fuel yields. Discover optimization strategies in this comprehensive review on refinery process yields.

FAQs

What is LNG bunkering?

LNG bunkering is the process of supplying liquid natural gas as fuel to ships, offering a cleaner alternative to traditional marine fuels.

Why is LNG considered a safer fuel option for maritime operations?

LNG releases significantly fewer pollutants and has a lower risk of spills compared to oil-based fuels, making it a safer choice for shipping operations.

How can training help improve LNG management?

Proper training equips personnel with essential knowledge of LNG handling, safety protocols, and best practices, ensuring smooth and safe operations.

Conclusion

Managing LNG fuel and bunkering on ships may seem complex, but with the right mix of strategies, technology, and safety protocols, it can be navigated smoothly. Adopting best practices not only enhances fuel efficiency but also ensures compliance with environmental regulations. As the industry continues to evolve, staying updated through courses and resources will help stakeholders not just adapt, but thrive. In summary, LNG isn’t just the fuel of the future; it represents a significant step towards greener maritime operations, leading a broader transformation within the industry.