Table of Contents

- Introduction

- Understanding the Importance of Yield Optimization

- Key Principles of Refinery Process Yields

- Advanced Techniques for Yield Optimization

- Benefits of Enhanced Yield Optimization

- Training Options for Professionals

- Frequently Asked Questions

- Conclusion

Introduction

Refining petroleum involves complex processes, and the pursuit of efficiency throughout these processes is paramount. Refinery yield optimization focuses on maximizing the output from raw materials and minimizing waste, ultimately benefiting both the environment and the bottom line. Therefore, understanding the intricacies of these processes is essential for those working within the industry.

Understanding the Importance of Yield Optimization

Why should professionals in the petroleum sector prioritize yield optimization? The answer lies in the foundational benefits of enhanced productivity and reduced operational costs. As industry demands continue to evolve, maintaining competitive edge becomes increasingly critical.

### H3>Environmental and Economic Impact

By focusing on yield optimization, refiners contribute to reducing environmental footprints through the efficient use of resources. Additionally, improving yield translates to increased profitability. Consequently, both the environment and the economy gain from robust yield optimization practices.

### H3>Regulatory Compliance

Furthermore, adherence to tightening regulations concerning emissions and effluent management necessitates enhanced process efficiency. Hence, yield optimization aligns not only with industry best practices but also with legal mandates.

Key Principles of Refinery Process Yields

Understanding the key principles behind refining processes reinforces the knowledge required to optimize yields effectively.

### H3>Feedstock Quality

First and foremost, the quality of raw materials significantly influences overall yields. Higher-quality feedstocks often result in better processing outcomes. Therefore, rigorous testing and quality assurance of incoming materials can make a significant difference.

### H3>Process Control

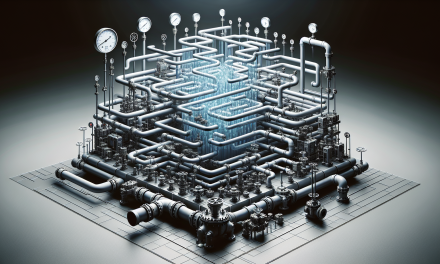

Moreover, effective process control techniques play an integral role in optimizing yields. Advanced control systems, alongside thorough training, can enhance performance across various refining units. Implementing state-of-the-art technology further assists in monitoring real-time data, facilitating immediate corrective actions when needed.

### H3>Energy Efficiency

Energy consumption also directly affects yields. Optimizing energy use not only cuts costs but can significantly increase the efficiency of operations. As a result, investing in energy-efficient technologies proves beneficial in various aspects.

Advanced Techniques for Yield Optimization

When exploring the landscape of yield optimization, professionals encounter various advanced methods that significantly enhance performance throughout refinery processes.

### H3>Simulation Software

Beginning with simulation software, these tools allow engineers to model refinery processes and predict outcomes under different scenarios. For instance, professionals use these simulations to test new configurations or process parameters, helping to identify optimal operating conditions.

### H3>Data Analytics

In addition to simulation software, leveraging data analytics helps uncover patterns and correlations within refinery operations. By analyzing historical performance data, refiners gain insights into their processes, leading to informed decisions that enhance yield.

### H3>Refinery Yield Optimization & Process Training Course

Furthermore, continual learning and development opportunities such as the Refinery Yield Optimization & Process Training Course provide valuable knowledge on the latest optimization techniques and technologies, ensuring that professionals remain at the forefront of industry advancements.

Benefits of Enhanced Yield Optimization

The advantages of a well-optimized refinery yield are numerous and multifaceted. They encompass both operational improvements and broader industry impacts.

### H3>Cost Reduction

Firstly, reducing operational costs ranks among the most immediate benefits. Enhanced yields mean that refiners can minimize feedstock use while maximizing outputs. In turn, this efficiency fuels favorable economic performance.

### H3>Improved Product Quality

More importantly, optimizing refining processes often leads to superior product quality. Higher-quality outputs are not only more marketable but also reflect positively on the company’s reputation. Thus, a commitment to yield optimization supports overall brand integrity.

### H3>Workforce Empowerment

Moreover, investing in worker training fosters a culture of continuous improvement. As employees enhance their skills regarding process optimization, they become more adept at identifying issues and formulating solutions. This empowerment ultimately leads to a more knowledgeable and effective workforce, driving organizational success.

Training Options for Professionals

In the quest for yield optimization, professionals have access to various training options that cater to their unique needs and learning preferences.

### H3>Comprehensive Safety Audit and Site Inspection Training

For example, engaging in a comprehensive safety audit and site inspection training enhances not only personal skills but also aligns efficiency with safety protocols.

### H3>Understanding Petroleum Reservoir Fluid Dynamics

Additionally, a solid understanding of petroleum reservoir fluid and phase behavior is crucial: delving into this topic allows professionals to optimize how fluids behave under varying conditions. Resources such as Understanding Petroleum Reservoir Fluid and Phase Behavior offer insights that refine one’s approach to yield optimization.

### H3>Skill Enhancement in Oil Production

Seeing an increase in facility efficiency is essential. Thus, enhancing skills in oil production and processing facilities fosters both individual competence and organizational growth, preparing professionals to tackle modern challenges.

### H3>Mastering Gas Chromatography

Furthermore, mastering techniques, such as gas chromatography in the oil and gas industry, greatly aids in troubleshooting and optimizing processes. Learning best practices through guides like Gas Chromatography in the Oil & Gas Industry can significantly improve outcomes within refineries.

### H3>Comprehensive Power Generation Knowledge

Finally, understanding broader concepts such as power generation through steam turbines and gas turbines aids experts in refining sectors. For those interested, the guide on Understanding Power Generation provides a solid foundation for advancements in overall process efficiency.

Frequently Asked Questions

### H3>What are the primary benefits of yield optimization in refining?

The key benefits include reduced operational costs, enhanced product quality, compliance with regulations, and a more empowered workforce.

### H3>How can simulation software assist in yield optimization?

Simulation software allows users to model various refinery processes and predict outcomes, which helps identify optimal conditions to enhance yield.

### H3>Where can I find relevant training resources?

Many resources are available, including the Refinery Yield Optimization & Process Training Course and various articles covering topics from safety audits to gas chromatography.

Conclusion

In conclusion, optimizing refinery processes yields significant benefits, both operationally and financially. Through understanding key principles, implementing advanced techniques, and engaging in continuing education, professionals can drive their organizations to new heights of efficiency and effectiveness. Ultimately, a commitment to refining yield optimization not only fosters personal growth and expertise but also significantly enhances industry standards.