Table of Contents

- Introduction

- Understanding ASME B31.3

- Importance of ASME B31.3 in Process Piping

- Key Design Principles

- Material Selection Process

- Welding Techniques and Considerations

- Testing and Inspection Standards

- Best Practices for Implementing ASME B31.3

- Conclusion

- FAQs

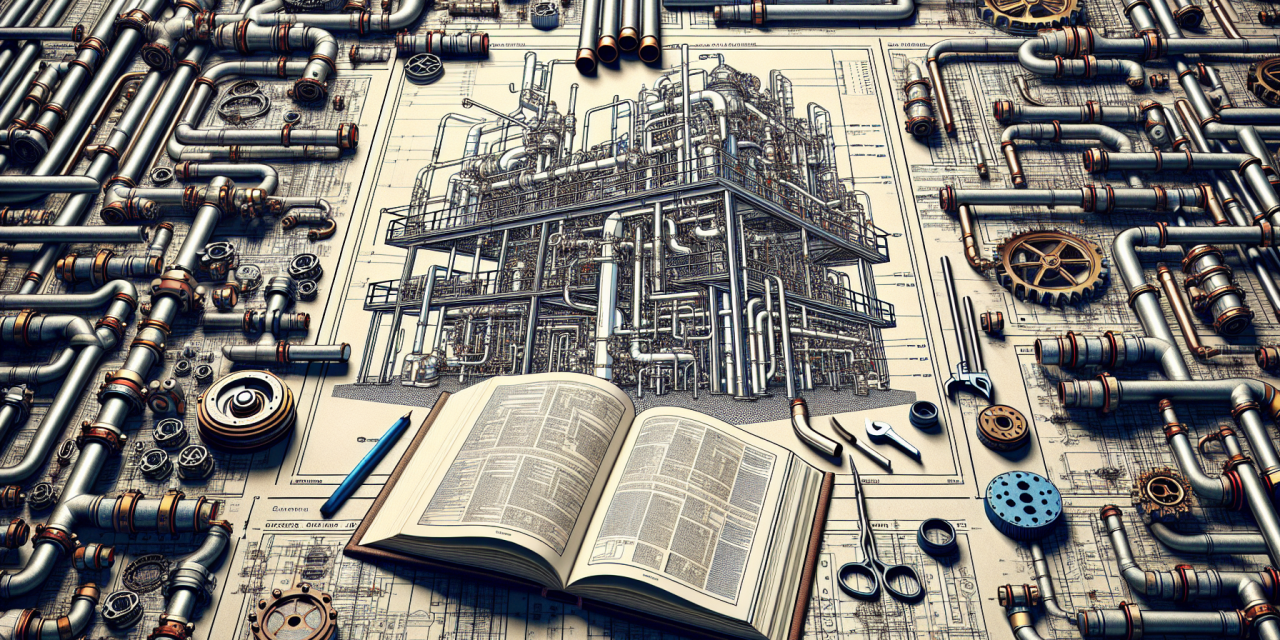

Introduction

The ASME B31.3 Process Piping Design Code serves as a critical framework for the design and maintenance of process piping in various industries, especially chemical and petroleum. Understanding this code ensures safety, reliability, and compliance in piping systems. Thus, diving into the details of ASME B31.3 offers valuable insights.

Understanding ASME B31.3

ASME B31.3 is a section of the ASME (American Society of Mechanical Engineers) B31 Code for Pressure Piping. It specifically covers process piping that includes piping systems that manage fluid flow in industrial settings. This code applies various essential elements ranging from materials and design to fabrication and installation. Therefore, familiarizing oneself with these specifications is crucial for engineers and technicians alike.

Scope of ASME B31.3

With a broad scope encompassing various industries, ASME B31.3 also includes guidelines for pressure vessels, piping systems handling corrosive substances, and even thermal expansion considerations. Such guidelines help professionals ensure that their designs meet not only safety standards but also operational efficiency.

Importance of ASME B31.3 in Process Piping

Following the ASME B31.3 code positively impacts numerous facets of process piping. For example, it directly influences safety protocols, ultimately reducing the likelihood of leaks and failures. Additionally, compliance with these standards minimizes costly accidents that could arise from poorly designed or maintained piping systems.

Enhancing Safety

When professionals adhere to the guidelines set forth in ASME B31.3, they significantly enhance the safety of their operations. This rigorous standardization allows engineers to evaluate the risks associated with their projects thoroughly. Moreover, it promotes safer work environments.

Boosting Efficiency

Besides safety, ASME B31.3 also emphasizes operational efficiency. Implementing the design principles outlined in the code helps maximize fluid movement through pipelines. By focusing on minimizing friction and other involuntary characteristics, professionals can improve their systems’ overall performance.

Key Design Principles

Several design principles lay the groundwork for piping systems. Incorporating these principles within the ASME B31.3 framework ensures that all projects conform to high standards.

Load Considerations

Engineers must assess various loads acting on piping systems, including dead weight, pressure, seismic, and thermal loads. Consequently, understanding how forces interact allows for well-balanced designs that can withstand real-world conditions.

Dead Weight and Internal Pressure

The dead weight of the piping material itself and internal pressure are primary considerations. These two factors can significantly influence design specifications, as they directly correlate to the strength and integrity required for the system.

Flexibility and Thermal Expansion

Piping systems must account for temperature changes that contribute to expansion and contraction. Flexible piping design allows for these variations, preventing mechanical failure or damage. Thus, appropriate support and anchoring strategies are crucial.

Material Selection Process

Choosing the right materials is imperative in ensuring long-lasting integrity and functionality of process piping. Various factors come into play during material selection, and ASME B31.3 helps identify the best materials while promoting safety and durability.

Corrosion Resistance

Corrosion poses a significant risk in process piping. Therefore, selecting materials resistant to corrosion is vital for longevity. Various coatings and alloys enhance the resistance of piping systems, allowing them to function effectively in harsh environments.

Temperature Compatibility

Compatibility with temperature ranges also drives material choice. Piping must withstand the thermal conditions it will encounter, thereby preventing failures that could stem from excessive heat or cold.

Welding Techniques and Considerations

Welding serves as a vital process in joining various materials in piping systems. Techniques and methods must conform to ASME B31.3 standards, ensuring robust connections and integrity.

Welding Procedures

Establishing approved welding procedures guarantees that all welds meet the required specifications. Engineers and technicians must ensure they utilize qualified operators and appropriate techniques, aligning with the code’s requirements. More effective joints significantly minimize the likelihood of leaks and failures.

Inspection of Welds

Also, proper inspection techniques validate the quality of welds. Various methods, such as visual inspections and non-destructive tests, assure that every joint meets safety and operational standards.

Testing and Inspection Standards

Following design and construction phases, testing and inspection ensure the reliability of piping systems. ASME B31.3 emphasizes rigorous standards that professionals must adhere to.

Types of Testing

Multiple testing methods are available, ranging from hydrostatic testing to pneumatic testing. These tests verify that the piping systems can handle operational pressures safely.

Routine Inspection

Regular inspections contribute to maintaining high standards. Follow-up checks during operation help identify any unforeseen issues early on, ensuring that the systems remain safe and effective over time.

Best Practices for Implementing ASME B31.3

Understanding and applying best practices when working with ASME B31.3 lends itself to effectively maintaining piping systems. Professionals must continuously improve their knowledge and adapt accordingly.

Continuous Learning

Engaging in ongoing education and training regarding ASME B31.3 principles is essential for engineers and technicians. Valuable resources, such as the ASME B31.3 Process Piping Design Code Certification Course, provide vital insights.

Industry Trends and Updates

Staying updated with evolving industry trends helps professionals apply the latest best practices and technologies. This ultimately contributes to improved safety and efficiency across projects.

FAQs

What type of industries utilize ASME B31.3?

ASME B31.3 finds application across various industries, particularly in oil and gas, chemical processing, and power generation sectors. Essentially, any industry relying on process piping can incorporate these standards.

How often should inspections be conducted?

Frequency of inspections largely depends on the type of system and its operational history. However, routine inspections are generally recommended to ensure ongoing system integrity.

Conclusion

Ultimately, the ASME B31.3 Process Piping Design Code plays a crucial role in ensuring safety and efficiency in piping systems. With its emphasis on design principles, material selection, and rigorous testing standards, this code sets a high bar for industrial piping practices. Professionals who continuously adapt and align their operations with these standards will undoubtedly contribute to safer and more efficient systems in the long run. Moreover, keeping abreast of other relevant topics, such as oil and gas production operations, asset integrity management, and LNG fuel management, further solidifies one’s understanding of industry standards. Additionally, exploring subjects related to corrosion control strategies and pipeline operations and maintenance can enhance your overall prowess in process piping design.