Table of Contents

- Introduction

- Understanding Solid Transport

- Methods of Solid Transport

- Applications of Solid Transport

- Choosing the Right Method

- Recent Advancements in Technology

- Key Takeaways

- FAQs

- Conclusion

Introduction

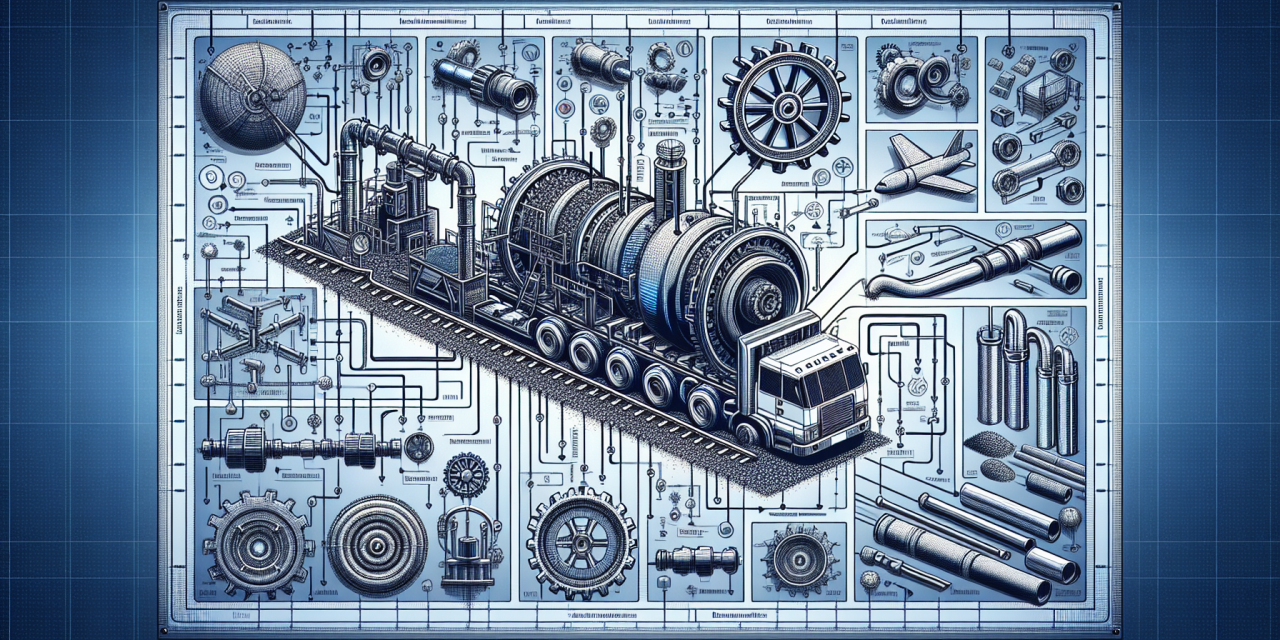

The transport of solids plays a pivotal role across numerous industries such as mining, food production, and pharmaceuticals. In this dynamic field, various methods exist to ensure efficient and effective movement of materials. Specifically, hydraulic and pneumatic conveying systems stand out due to their unique advantages. Exploring these systems not only enhances our understanding but also equips industry professionals with the necessary tools to optimize processes.

Understanding Solid Transport

Solid transport refers to the movement of solid materials from one location to another. This process can be quite complex, as different materials present various challenges in terms of their physical properties, such as size, weight, and abrasiveness. Whether it’s moving granular substances like sugar or bulk materials like gravel, solid transport requires careful planning and execution.

Methods of Solid Transport

When it comes to transporting solids, two primary methods stand out: hydraulic conveying and pneumatic conveying. Each method has its specific applications and advantages. Let’s delve deeper into both systems.

Hydraulic Conveying

Hydraulic conveying utilizes the power of pressurized liquid to transport solid materials. By mixing the solids with a liquid, the hydraulic system creates a slurry, which moves through pipes or other channels.

Advantages of Hydraulic Conveying:

- Efficient for transporting heavy or dense materials.

- Reduces wear and tear on transport equipment.

- Can handle high concentrations of solids.

However, it’s crucial to manage hydraulic systems properly to avoid issues such as segregation of solids, which can hinder efficiency.

Pneumatic Conveying

Pneumatic conveying, on the other hand, uses gas (often air) to transport solid materials. In this system, solids move in a stream of air through conveyor pipelines.

Advantages of Pneumatic Conveying:

- Ideal for lightweight or fine materials.

- Offers flexibility in routing due to the lighter nature of the conveying medium.

- Minimizes the risk of contamination and oxidation.

Nonetheless, pneumatic conveying systems can face challenges such as material fluidization and the need for proper system design to avoid blockages.

Applications of Solid Transport

The applications of solid transport systems are vast and varied. Industries like construction rely on these systems to move aggregates, while food production facilities use them for transporting ingredients like flour and sugar. Furthermore, other sectors such as pharmaceuticals and petrochemicals also depend on effective solid transport methodologies to ensure product quality and operational efficiency.

Choosing the Right Method

Selecting the appropriate method for transporting solids depends on several factors, including the type of material, desired transport distance, and environmental considerations. Understanding the unique properties of the solid being transported is critical. While hydraulic systems may be more suitable for heavy and dense materials, pneumatic systems are often more advantageous for lightweight particles or dust.

Additionally, one can consult resources such as the Hydraulic & Pneumatic Conveying Systems Course for deeper insight into making the right choice for specific applications.

Recent Advancements in Technology

Innovations in technology continue to reshape the landscape of solid transport systems. Moreover, industry leaders are focused on enhancing the efficiency and safety of these systems. Advanced sensor technology, automation, and data analytics play significant roles in optimizing the transport of solids.

For instance, sensors help monitor the flow of materials in real-time, allowing operators to make informed decisions and troubleshoot issues before they escalate. Similarly, automation reduces manual intervention, thus minimizing the potential for human error.

To further explore the challenges faced in industrial contexts, consider reading articles such as Navigating the Complexities: Materials and Welding Challenges in Offshore Oil & Gas Industries and Enhancing Resilience in Process Equipment and Piping.

Key Takeaways

- The transport of solids is vital for multiple sectors, including construction and food production.

- Hydraulic and pneumatic conveying systems are two primary methods used for solid transport.

- Choosing the right method hinges on material characteristics and transport systems.

- Recent technological advancements significantly enhance efficiency and safety in the transport process.

FAQs

What is hydraulic conveying?

Hydraulic conveying is a method that uses pressurized liquid to transport solid materials mixed into a slurry.

What materials are best suited for pneumatic conveying?

Pneumatic conveying is optimal for lightweight and fine materials such as flour, powders, and pellets.

Why should one consider automation in solid transport systems?

Automation minimizes human error and increases productivity in handling and transporting solid materials.

How can I improve the efficiency of a solid transport system?

Improving operational efficiency often involves monitoring flow conditions, proper system design, and exploring advanced technologies.

Conclusion

Understanding the intricacies of solid transport mechanisms is essential for engineers and industry operators alike. By leveraging the strengths of hydraulic and pneumatic conveying systems, organizations can enhance operational efficiency and achieve superior material handling outcomes. To delve deeper into the nuances of these systems, further reading and learning opportunities await!

For comprehensive insights into process equipment design, application, and maintenance strategies, check out the following resources: Mastering Process Equipment and Piping Systems, Comprehensive Guide to Process Equipment and Piping Systems, and Mastering Process Plant Troubleshooting.