Table of Contents

- Introduction

- Importance of Advanced Maintenance Planning

- Best Practices for Effective Maintenance Planning

- Techniques for Successful Scheduling

- Overcoming Common Challenges

- Advanced Topics in Maintenance

- FAQs

- Conclusion

Introduction

In today’s fast-paced industrial environment, effective maintenance is an absolute necessity. Tackling unforeseen equipment failures and operational disruptions has become a challenge for many organizations. Hence, mastering advanced maintenance planning and scheduling is crucial for all maintenance professionals.

The Role of Maintenance in Operations

Operational efficiency significantly hinges on effective maintenance strategies. By reducing downtime and maximizing equipment lifespan, organizations can improve productivity and save costs. To achieve these benefits, it’s vital to understand advanced techniques that elevate maintenance from a reactive approach to a proactive one.

Importance of Advanced Maintenance Planning

Understanding the importance of advanced maintenance planning cannot be overstated. Maintenance practices have evolved from simple repairs to comprehensive management systems that require a strategic approach.

Benefits of Advanced Maintenance Planning

- Increased Efficiency: Planning maintenance helps streamline operations, thus ensuring every team member knows their responsibilities.

- Cost-Effectiveness: A well-maintained system decreases unnecessary expenditures, improving the bottom line.

- Enhanced Safety: Proper maintenance minimizes risks, thereby safeguarding employees and assets.

The Business Impact

Moreover, effective maintenance strategies drive better performance. Consequently, this leads to an organization’s enhanced reputation and competitiveness in the market.

Best Practices for Effective Maintenance Planning

To establish a robust maintenance plan, it is essential to incorporate best practices that many successful organizations utilize.

Define Clear Objectives

Start by defining clear, measurable objectives for your maintenance planning. This goal-setting provides direction and helps track progress over time.

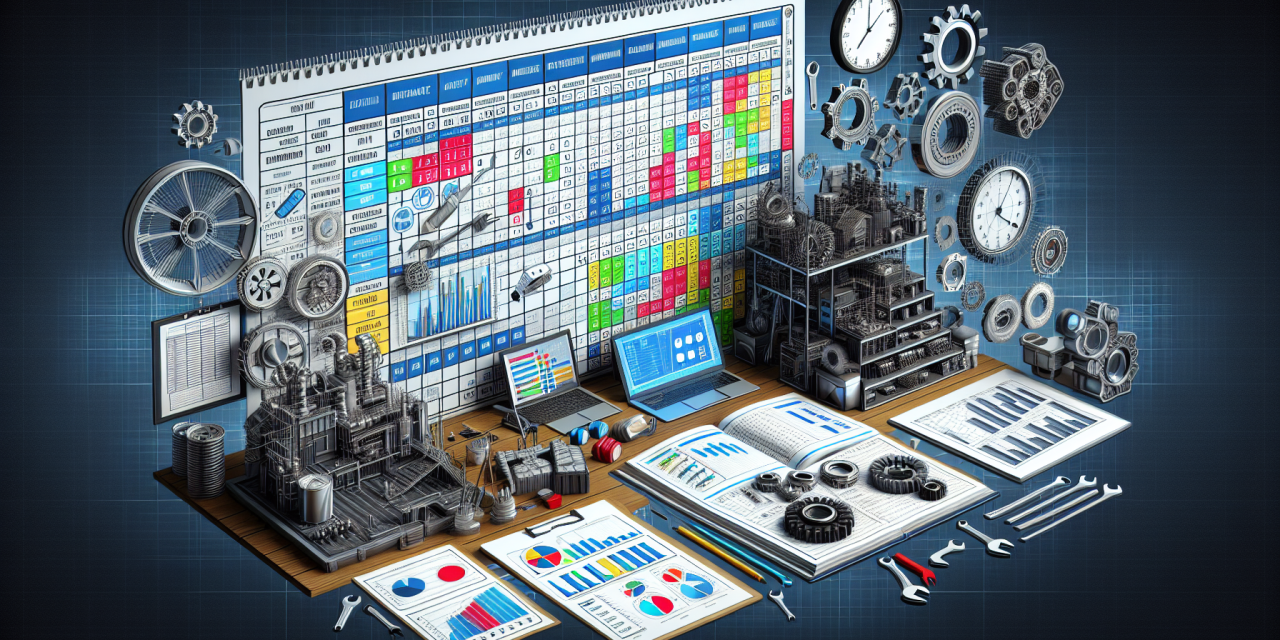

Utilize Technology

Incorporating modern technology plays a significant role in planning maintenance tasks effectively. Management software aids in tracking schedules and resource allocation while automating reminders for tasks.

Real-Time Data Utilization

Furthermore, employing real-time data analytics allows maintenance professionals to anticipate issues before they escalate into major repairs. By leveraging insights from historical data, teams can make informed decisions that lead to better maintenance outcomes.

Techniques for Successful Scheduling

Effective scheduling is just as important as planning. Implementing the following techniques can help create a more structured and reliable scheduling system.

Prioritization of Tasks

Not all maintenance tasks hold the same level of urgency. By prioritizing tasks based on their impact on operations, maintenance teams can allocate resources effectively.

Regular Review and Adjustments

Regularly reviewing maintenance schedules ensures they remain relevant. Adjustments based on shifting operational needs can prevent scheduling conflicts and bottlenecks.

Incorporating Feedback

Moreover, incorporating feedback from team members accelerates the improvement of scheduling processes. Their on-the-ground experiences provide valuable insights that can lead to innovative scheduling solutions.

Overcoming Common Challenges

Despite the benefits of planning and scheduling, many organizations face challenges that can hinder their maintenance efforts. Addressing these can enhance overall effectiveness.

Resistance to Change

Introducing advanced planning approaches may encounter resistance from staff accustomed to traditional methods. Emphasizing the benefits and providing adequate training can ease this transition.

Resource Limitations

Often, organizations struggle with limited resources—be it manpower, time, or budget. Developing a well-defined strategy that optimizes resource use can mitigate these limitations.

Advanced Topics in Maintenance

To truly master maintenance planning and scheduling, exploring advanced topics is essential. A deeper understanding leads to refined strategies and methodologies.

Reliability-Centered Maintenance (RCM)

RCM is an advanced approach aimed at ensuring systems continue to do what their users require in their present operating context. Embracing RCM helps organizations align maintenance strategies with reliability objectives.

Predictive Maintenance Techniques

Predictive maintenance harnesses technology, such as IoT (Internet of Things), to predict equipment failures before they occur. Therefore, utilizing predictive techniques allows for more strategic maintenance planning.

Additionally, if you want to dive deeper into advanced strategies and really boost your skills in planning and scheduling, you might want to check out this resource: Advanced Maintenance Planning & Scheduling Training Course.

FAQs

What is the key benefit of advanced maintenance planning?

The primary benefit lies in increased operational efficiency and reduced costs. It allows organizations to better anticipate equipment needs, leading to fewer breakdowns and unplanned downtimes.

How can technology improve maintenance planning?

Technology streamlines maintenance processes by providing tools for tracking schedules, analyzing data, and automating routine tasks, making the entire maintenance operation smoother.

Conclusion

In conclusion, mastering advanced maintenance planning and scheduling is an essential aspect of modern industrial operations. By implementing effective strategies, embracing new technologies, and overcoming common challenges, organizations can significantly enhance their maintenance practices. Remember to engage your team, continually review your strategies, and adapt as needed to ensure ongoing success. With the right knowledge and skills, the benefits can profoundly impact your organization’s efficiency and bottom line.