Table of Contents

- Introduction

- The Importance of Flow Measurement

- Flow Measurement Technologies

- Overcoming Challenges in Flow Measurement

- Enhancing Expertise in Flow Measurement

- Benefits of Proficiency in Flow Measurement

- Frequently Asked Questions

- Conclusion

Introduction

In the dynamic world of oil and gas, mastering flow measurement techniques can significantly enhance operational efficiency and safety. Professionals engaged in oil and gas processing encounter an array of challenges and complexities. Consequently, developing a deep understanding of flow measurement technologies is essential.

The Importance of Flow Measurement

Accurate flow measurement plays an indispensable role in oil and gas operations. For instance, companies rely on precise flow readings to ensure regulatory compliance, optimize production levels, and maintain operational safety. Moreover, effective flow measurement contributes to the accurate allocation of resources and the management of supply chain dynamics.

Ensuring Compliance and Safety

Regulatory compliance is paramount in the oil and gas industry. Agencies mandate accurate reporting of flow data, with strict guidelines governing operational practices. Beyond compliance, maintaining safety standards is a primary concern. Inaccurate flow measurements can lead to hazardous situations, making proficiency in measurement techniques vital.

Optimizing Production and Resource Allocation

Optimizing production directly correlates with effective flow measurement. A thorough understanding of flow dynamics enables professionals to identify production bottlenecks and inefficiencies. Consequently, organizations can make informed decisions about resource allocation, ensuring that every drop of crude oil or gas is accounted for optimally.

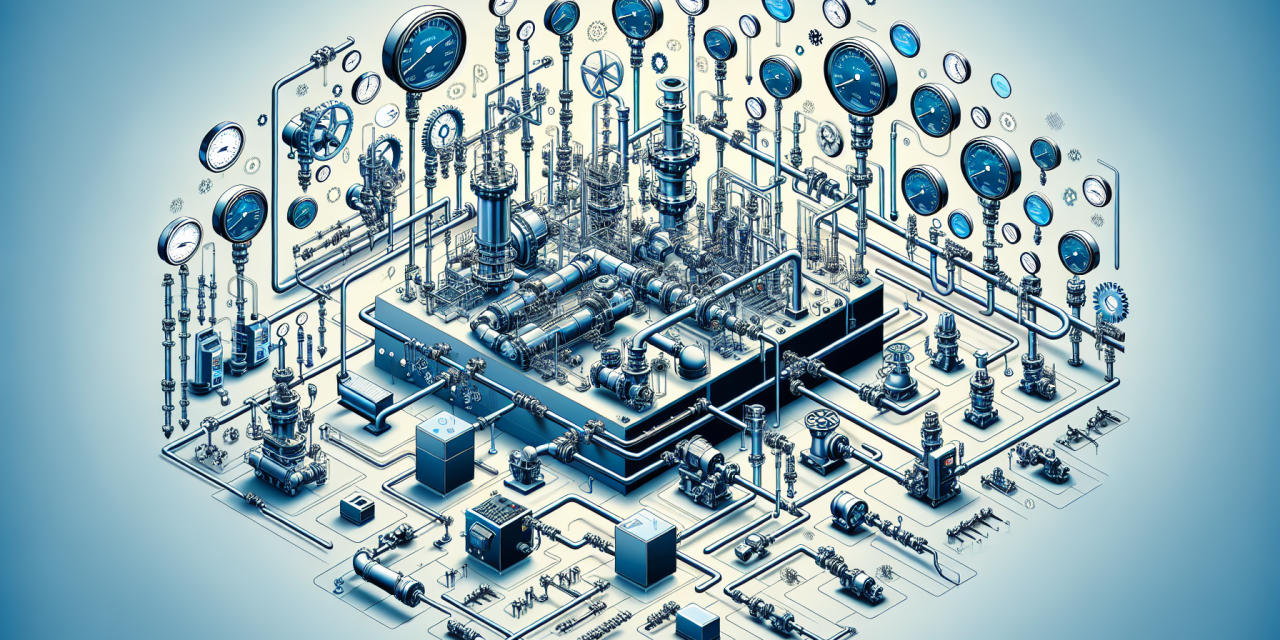

Flow Measurement Technologies

Various technologies exist for measuring flow in oil and gas operations. Each technology has its unique strengths and weaknesses, and selecting the appropriate method depends on specific operational requirements.

Types of Flow Measurement Technologies

- Orifice Plates: A traditional mechanism, orifice plates measure flow by creating a pressure drop in the fluid.

- Flow Meters: These devices, such as turbine and electromagnetic meters, provide real-time flow data.

- Ultrasonic Flow Measurement: Utilizing sound waves, ultrasonic devices offer non-intrusive measurements with high accuracy.

Choosing the Right Technology

When selecting a flow measurement technology, several factors warrant consideration, including fluid properties, pressure, temperature, and environmental conditions. Understanding these factors can aid professionals in making informed decisions tailored to their operational needs.

Overcoming Challenges in Flow Measurement

Despite advancements in measurement technologies, professionals continually face challenges within flow measurement systems. Identifying and addressing these hurdles is essential for optimizing operations.

Common Challenges

- Fluid Characteristics: Variations in fluid viscosity and density can impact measurement accuracy.

- Installation Issues: Improper installation of measuring devices often leads to unreliable readings.

- Environmental Factors: Harsh environmental conditions can affect measurement performance.

Strategies for Successful Measurement

Implementing best practices, such as routine calibration and maintenance, can mitigate challenges associated with flow measurement. Continuous monitoring and assessment of measurement accuracy also contribute to overcoming potential obstacles.

Enhancing Expertise in Flow Measurement

Professionals can significantly benefit from honing their expertise in flow measurement techniques. A structured approach to gaining knowledge will yield immense returns in operational efficiency.

Continuous Learning Opportunities

As technology evolves, continual learning becomes imperative. For instance, participating in specialized training sessions that focus on Oil and Gas Processing Flow Measurement can help professionals stay abreast of the latest technologies and methodologies. Finding relevant training programs, such as the Oil and Gas Processing Flow Measurement Course Certification, provides structured learning and expert insights.

Networking and Collaboration

Engaging with peers in the industry fosters knowledge sharing of new techniques and best practices. Joining professional associations and attending conferences can further expand one’s network, unlocking new opportunities for collaboration.

Benefits of Proficiency in Flow Measurement

Exceling in flow measurement practices leads to several benefits that enhance both career prospects and organizational performance. Understanding these advantages becomes crucial for professionals in the field.

Enhancing Career Opportunities

Gaining expertise in flow measurement not only solidifies one’s positioning within the industry but also expands career opportunities. Employers seek professionals capable of navigating the complexities of measurement techniques and ensuring operational compliance.

Boosting Organizational Performance

Organizations that prioritize flow measurement accuracy can reap significant rewards. Enhanced production efficiency, reduced downtime, and improved safety standards contribute to overall operational success.

Additional Resources

In addition to focusing on flow measurement, professionals can broaden their knowledge by exploring related areas. Topics such as the ISM Code for Maritime Offshore Safety and Gas Conditioning and Processing showcase the vast landscape of knowledge beneficial for oil and gas professionals.

Frequently Asked Questions

What is flow measurement?

Flow measurement refers to the process of quantifying the flow rate of liquids, gases, or slurry transported through a conduit. Accurate measurements help in monitoring and controlling production environments.

Why is flow measurement critical in oil and gas?

Precise flow measurement is critical in oil and gas to maintain safety, ensure compliance with regulations, and optimize production processes. It directly impacts the efficiency of operations and reduces the risk of errors.

How can companies improve flow measurement accuracy?

Companies can improve flow measurement accuracy through regular calibration, choosing appropriate measurement technologies, and investing in training programs focused on fluid dynamics.

Conclusion

In summary, proficiency in oil and gas processing flow measurement stands as a vital skill for professionals in the industry. By addressing the challenges associated with measurement, embracing continued education, and understanding the advantages of accurate flow measurement, individuals can significantly enhance their capabilities. Moreover, exploring additional facets such as Project Management in Oil & Gas and Opportunities in Exploration and Production can further enrich professional development. As the oil and gas industry continues to evolve, remaining equipped with the necessary knowledge will pave the way for success.