Table of Contents

- Introduction to Heat Exchangers

- Types of Heat Exchangers

- Shell and Tube Heat Exchangers

- Plate Heat Exchangers

- Air-Cooled Heat Exchangers

- Double Pipe Heat Exchangers

- Spiral Heat Exchangers

- Applications of Heat Exchangers

- Design Considerations for Heat Exchangers

- Operating Principles

- Maintenance Practices

- FAQs

- Conclusion

Introduction to Heat Exchangers

Heat exchangers are essential components in many industrial and commercial applications. They facilitate the transfer of heat between two or more fluids without the fluids mixing. This functionality makes them crucial for energy efficiency and system effectiveness. Whether in heating, cooling, or heat recovery systems, understanding heat exchangers will empower engineers and technicians alike to optimize performance.

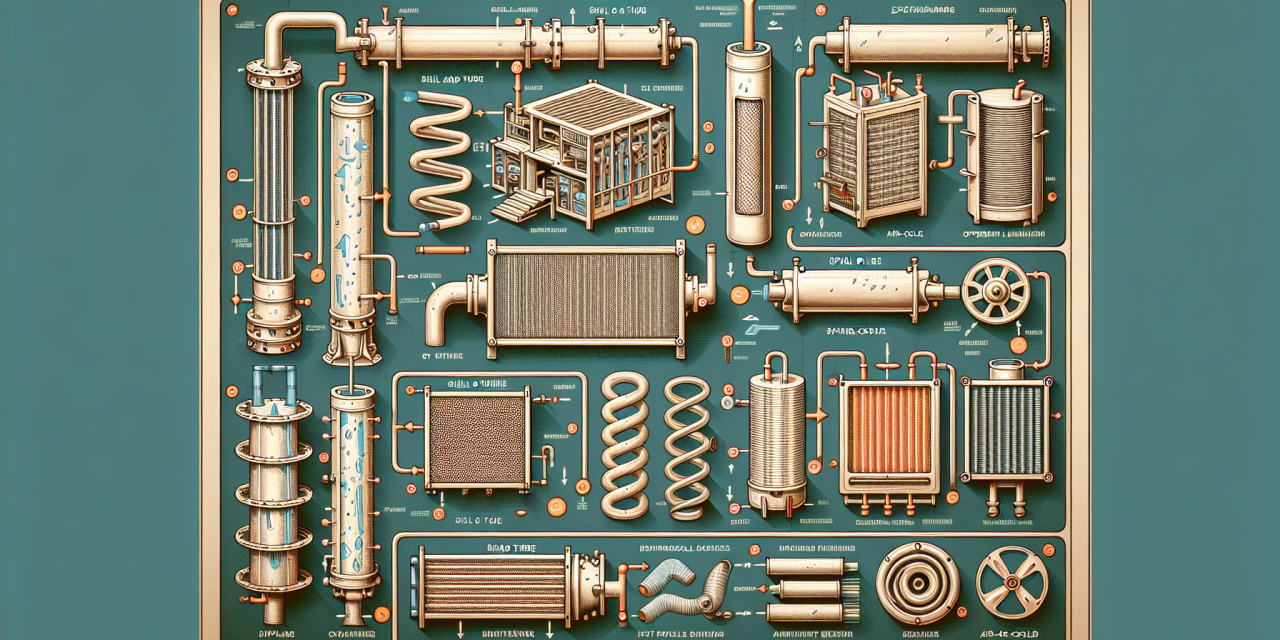

Types of Heat Exchangers

In this section, we will explore the various types of heat exchangers, each designed for specific applications and operating conditions.

Shell and Tube Heat Exchangers

Shell and tube heat exchangers comprise a series of tubes, one set carrying the hot fluid and another carrying the cold fluid. These heat exchangers are widely used due to their high efficiency and ability to handle large temperature differences. Industries like oil and gas, power generation, and chemical processing utilize them extensively.

Plate Heat Exchangers

Plate heat exchangers consist of multiple thin plates arranged to create channels for the fluids. This design significantly enhances heat transfer efficiency. As a result, plate heat exchangers occupy less space and are often cleaner than shell and tube designs, making them ideal for food and beverage applications.

Air-Cooled Heat Exchangers

Air-cooled heat exchangers use air to remove heat from a working fluid. These systems usually consist of finned tubes and fans that circulate air. They are particularly useful in locations where water is scarce. Industries often use air-cooled heat exchangers for outdoor installations and in regions with limited water access.

Double Pipe Heat Exchangers

A double pipe heat exchanger features one pipe inside another. Hot and cold fluids flow in opposite directions, enhancing heat transfer. Although they generally have a lower heat transfer efficiency compared to shell and tube heat exchangers, they are simpler and cost-effective, making them suitable for small scale applications and laboratory setups.

Spiral Heat Exchangers

Spiral heat exchangers consist of two spiral channels, where the hot and cold fluids travel in a countercurrent arrangement. This configuration increases the heat transfer area and improves thermal efficiency. Many industries opt for spiral heat exchangers when dealing with viscous fluids or when space is at a premium.

Applications of Heat Exchangers

Understanding the applications of heat exchangers reveals their versatility across numerous sectors. Below are some prominent fields where these devices play a significant role:

1. HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, heat exchangers are crucial for regulating indoor temperatures.

2. Chemical Processing

Heat exchangers support chemical reaction processes by controlling temperatures and maintaining required thermal conditions.

3. Power Generation

In power plants, heat exchangers facilitate heat recovery, improving system efficiency and reducing emissions.

4. Food and Beverage Industry

In these sectors, plate heat exchangers are popular for pasteurization processes, ensuring food safety and product quality.

5. Oil and Gas

Heat exchangers help in the process of refining crude oil and managing heat in various gas separation processes.

Design Considerations for Heat Exchangers

When designing a heat exchanger, several factors require attention to ensure effective operation:

1. Heat Transfer Efficiency

Designers must maximize surface area while minimizing pressure drop. Selecting the right type of heat exchanger based on the application is vital for achieving optimal performance.

2. Material Selection

Choosing the right materials is crucial, as they must withstand corrosive environments and high temperatures, especially in industries like chemical processing.

3. Flow Arrangement

The flow arrangement, whether counterflow, parallel flow, or crossflow, significantly impacts efficiency and must align with operational requirements.

4. Maintenance Access

Designing with maintenance in mind allows for easier cleaning and servicing, promoting longer equipment life.

Operating Principles

Understanding how heat exchangers operate is fundamental for anyone working with these devices. Key operating concepts include:

1. Thermodynamics

The principles of thermodynamics dictate how heat transfers between the fluids. Knowledge of temperature gradients aids in optimizing performance.

2. Flow Rates

Controlling and optimizing flow rates of the fluids can maximize heat transfer. This control enhances system responsiveness to changing operational demands.

3. Monitoring and Control Systems

Implementing monitoring systems allows continuous oversight of performance metrics, identifying any operational issues early.

Maintenance Practices

Proper maintenance of heat exchangers is crucial to prolonging their lifespan. The following practices are essential:

1. Regular Inspections

Scheduling regular inspections to check for leaks, corrosion, or fouling can prevent more significant issues down the line.

2. Cleaning

Cleaning heat exchangers regularly helps maintain efficiency. Depending on the fluid and service conditions, different cleaning techniques may be necessary.

3. Performance Monitoring

Continually monitoring performance indicators will help detect deviations that may signal the need for maintenance or repairs.

4. Replacement of Parts

When components wear out, timely replacement is crucial to ensure the heat exchanger operates effectively.

For those looking for comprehensive training on heat exchangers, consider the Heat Exchanger Course: Design, Types, Operation & Maintenance to get a deeper understanding of the topic.

FAQs

What is the primary purpose of a heat exchanger?

The primary purpose of a heat exchanger is to transfer heat between two or more fluids without allowing them to mix. This operation optimizes energy use in various applications, improving overall system efficiency.

How do I select the right type of heat exchanger for my needs?

To select the appropriate heat exchanger, consider factors such as the temperatures and pressures of the fluids, required heat transfer efficiency, space availability, and the specific application requirements.

Conclusion

Mastering heat exchangers requires knowledge of their types, applications, design principles, operating conditions, and appropriate maintenance practices. By understanding these elements, professionals can optimize heat exchanger performance and contribute to energy efficiency goals in their respective industries. For continuous improvement, seeking further education can be invaluable. Explore other related topics through these links: Navigating the Fundamentals of Finance and Accounting, Understanding Electrical Faults, Mastering Project Management, Effective Decision Analysis, and Mastering the Art of Contracts. By staying informed and educated, you’ll be well-equipped to tackle the challenges that come with working with heat exchangers.