Table of Contents

- Introduction

- Importance of Fluid Flow Control Systems

- Key Components of Fluid Flow Control Systems

- Techniques for Effective Fluid Control

- Challenges in Fluid Flow Control

- The Future of Fluid Flow Control

- Frequently Asked Questions

- Conclusion

Introduction

Fluid flow control systems play a crucial role in various industries, particularly in the process sector. They ensure that materials are transported efficiently and safely, thereby maximizing productivity. In this blog post, we will delve deep into the mechanics of fluid flow control systems, exploring their importance, components, and the techniques that enhance their functionality.

Importance of Fluid Flow Control Systems

In today’s fast-paced industrial landscape, fluid flow management is more critical than ever. For instance, effective control systems help maintain flow rates, ensuring consistent product quality. Furthermore, they contribute to safety by preventing leaks and accidents. To appreciate the significance of these systems, consider the following aspects:

- Consistency in Production: Reliable fluid flow control ensures that processes occur without interruptions, leading to a steady output.

- Cost Efficiency: By optimizing flow rates and reducing energy consumption, companies can save significantly on operational expenses.

- Safety: Proper control mechanisms prevent hazardous situations, making workplaces safer for employees and reducing the risk of environmental damage.

- Regulatory Compliance: Many industries face strict regulations regarding fluid transport. An effective control system helps adhere to these legal standards.

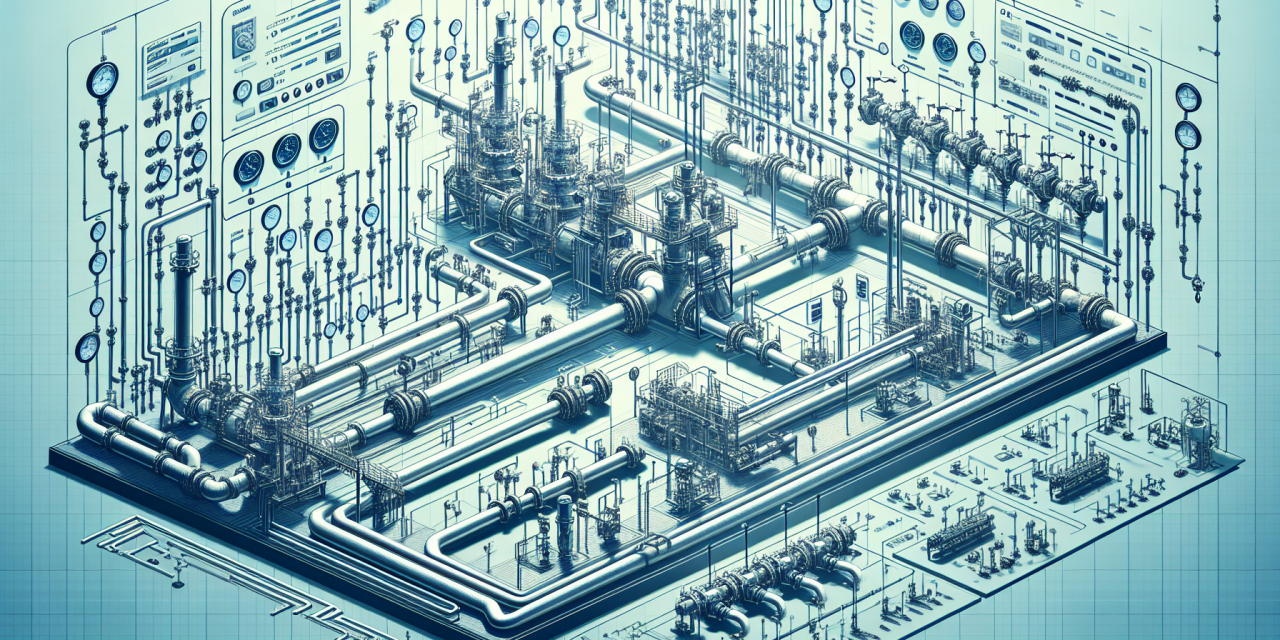

Key Components of Fluid Flow Control Systems

Pumps

Pumps are fundamental to fluid flow control systems. They are responsible for moving fluids through pipes and ensuring that the correct pressure is maintained. Whether the application involves water, chemicals, or other materials, selecting the appropriate pump type is vital.

Valves

Valves regulate the flow of fluids and pressure within the system. Various types of valves, including gate, globe, and ball valves, serve different purposes, and their proper selection and placement are essential for optimal performance.

Pipes and Fittings

Both pipes and fittings dictate how fluids travel through a system. Their material, diameter, and layout can significantly affect flow rates and pressure drops.

Flow Meters

To monitor and control the flow of fluids, flow meters provide real-time data. This information allows operators to make informed decisions regarding process adjustments.

Techniques for Effective Fluid Control

Real-Time Monitoring

Implementing real-time monitoring technologies, such as IoT sensors, allows for immediate detection of anomalies and swift adjustments.

Automation

Automation in fluid flow control streamlines operations. By integrating programmable logic controllers (PLCs) and advanced software, companies can enhance precision and reduce human error.

Regular Maintenance

Routine inspection and maintenance of equipment ensure that all components operate effectively. Failing to perform regular maintenance can lead to costly downtimes and potential hazards.

Challenges in Fluid Flow Control

Corrosion

Corrosion in pipelines can lead to significant issues, including leaks and failures. Regular inspections and the use of corrosion-resistant materials can mitigate this problem.

Fluid Properties

The variability of fluid properties, such as viscosity and temperature, can complicate flow control. Understanding these characteristics allows for better system design and component selection.

Environmental Factors

Environmental conditions, such as temperature extremes and pressure variations, can impact fluid flow. Designing systems that account for these factors is essential for reliable operations.

The Future of Fluid Flow Control

As technology evolves, the landscape of fluid flow control systems is changing. Trends point towards increased usage of automation, Artificial Intelligence (AI), and Data Analytics. These advancements lead to smarter, more adaptive systems that can respond to changing conditions instantly.

Additionally, the demand for sustainability in the process industry encourages innovation that minimizes resource wastage and maximizes energy efficiency. For those interested in exploring fluid flow control further, consider taking a look at the Fluid Flow Control Systems in Process Industries Course.

Frequently Asked Questions

What industries rely on fluid flow control systems?

Fluid flow control systems are prevalent in industries such as chemical manufacturing, oil and gas, water treatment, and food processing.

How can I ensure my fluid flow control system functions effectively?

Regular maintenance, real-time monitoring, and adopting automation technologies can significantly enhance the effectiveness of your fluid flow control system.

Are there any challenges in managing fluid flow?

Yes, challenges include corrosion, varying fluid properties, and environmental factors, all of which can affect flow stability and safety.

What can I do to mitigate corrosion in my fluid systems?

Using corrosion-resistant materials, implementing regular inspections, and employing protective coatings can effectively mitigate corrosion.

How does automation improve fluid flow control?

Automation enhances precision, reduces human error, and allows for real-time adjustments, significantly improving overall system performance.

Conclusion

In summary, fluid flow control systems are indispensable in the process industry. By understanding their components, adopting best practices, and being aware of potential challenges, businesses can optimize their operations. As we look to the future, advances in technology promise even greater improvements in efficiency and safety.

For more insights into related topics, check out these informative articles: Understanding Fluid Machinery: Mastering Operation and Maintenance of Pumps, Compressors, and Turbines, Mastering the Art of Solid Transport: A Comprehensive Guide to Hydraulic and Pneumatic Conveying Systems, Navigating the Complexities: Materials and Welding Challenges in Offshore Oil & Gas Industries, Enhancing Resilience in Process Equipment and Piping: Tackling Failures, Prevention Strategies, and Efficient Repair Techniques, and Mastering Process Equipment and Piping Systems: Application, Design, and Maintenance Strategies.