Table of Contents

- Introduction

- Understanding Cooling Towers

- Components of Cooling Towers

- Operation of Cooling Towers

- Maintenance of Cooling Towers

- Troubleshooting Cooling Towers

- Frequently Asked Questions

- Conclusion

Introduction

In today’s industrial landscape, cooling towers serve as crucial components for optimizing performance and ensuring efficiency. They play a vital role within various applications, from power plants to HVAC systems, by dissipating heat. However, understanding how cooling towers operate, maintaining them effectively, and troubleshooting potential issues can substantially impact the operational performance and reliability of entire systems.

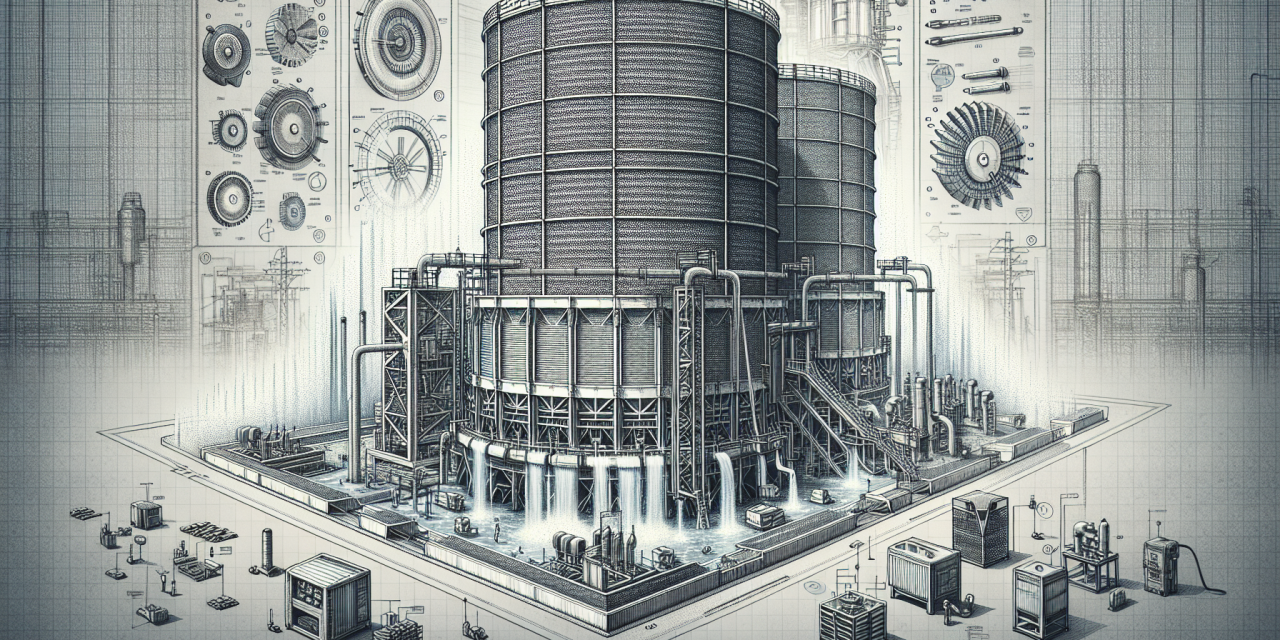

Understanding Cooling Towers

Cooling towers are thermal devices that transfer waste heat from one fluid to the environment through a cooling process involving evaporation. They typically cater to systems where large volumes of water circulate, absorbing heat generated from industrial processes, machinery, or other energy-utilizing systems.

The Importance of Cooling Towers

Properly functioning cooling towers contribute to energy efficiency by decreasing the temperature of water used in various industrial operations. Therefore, maintaining optimal cooling tower efficiency not only prevents overheating in machinery but also ensures that energy usage remains at lower costs.

Components of Cooling Towers

Understanding the components of cooling towers provides deeper insights into their operation and maintenance. Cooling towers generally consist of the following elements:

Fill Material

The fill material enhances the heat transfer process within the cooling tower. It allows water to distribute in thin films or small droplets, maximizing its exposure to air.

Fans

The fans draw air into the cooling tower, facilitating water and air interaction. They create the necessary airflow that supports the evaporation process.

Water Distribution System

This system ensures that water uniformly disperses over the fill material. Even distribution is key to maximizing the cooling tower’s efficiency.

Drift Eliminators

Drift eliminators trap and reclaim water droplets carried away by the airflow, reducing water wastage and enhancing efficiency.

Operation of Cooling Towers

The basic operation of cooling towers revolves around the principles of thermodynamics and fluid mechanics. As water circulates through the tower, it encounters air, dissipating its heat through evaporation.

The Cooling Process

When warm water enters the cooling tower, it passes through the fill material, where it is spread out into thin films. Simultaneously, ambient air is drawn in by the fans at the base of the tower. This interaction promotes the evaporation of water, allowing it to cool effectively. As a result, cooled water collects at the bottom and is pumped back into the system, repeating the cycle.

Factors Affecting Performance

- Environmental conditions, such as temperature and humidity, can influence cooling efficiency.

- The water quality, including the presence of contaminants, impacts fill material performance.

- Operational practices, such as regular maintenance and monitoring, are crucial to ensure effective operation.

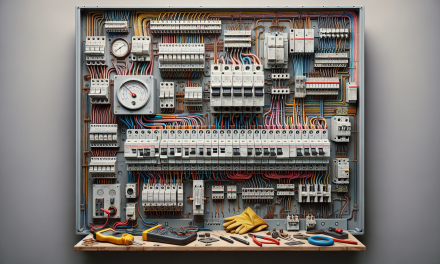

Maintenance of Cooling Towers

Regular maintenance is essential for optimizing cooling tower performance. Without proper attention, cooling towers may suffer from a range of issues that hinder their efficiency.

Regular Inspections

Conducting inspections on a regular basis helps identify potential problems early on. Technicians should examine components such as fill material, fans, and drift eliminators to ensure they function properly.

Water Treatment

Maintaining water quality is critical in preventing issues arising from scale, corrosion, and biological growth. Implementing appropriate water treatment programs, such as chemical dosing, helps minimize these risks. Regularly testing water quality ensures that necessary adjustments are made timely.

Cleaning Processes

Cleaning the cooling tower on a scheduled basis aids in the removal of debris, scale, and biological contaminants that can impair efficiency. A thorough cleaning ensures that the fill areas and other critical components remain unobstructed.

Replacement of Worn-Out Parts

Over time, components can deteriorate and fail. Timely replacement of fans, pumps, and water distribution systems minimizes disruption in operation and ensures optimal performance.

Troubleshooting Cooling Towers

Even with regular maintenance, cooling towers may still encounter problems. Understanding common issues and their solutions can significantly enhance operational reliability.

Common Problems

- Low Water Flow: This may result from clogged filters or malfunctioning pumps. Inspecting and clearing obstructions can resolve this issue.

- High Saturation Temperatures: Consequently, it may indicate inadequate airflow, perhaps due to malfunctioning fans or misaligned components. Ensuring that fans operate correctly and that there are no obstructions in the air intake can address this.

- Water Quality Issues: Algae and scale can accumulate if water treatment protocols are not followed. Implementing and maintaining a robust water treatment plan is essential for prevention.

For those looking to deepen their understanding of cooling towers, consider exploring the Cooling Tower Maintenance & Troubleshooting Training Course. This valuable resource effectively covers the operational intricacies, maintenance standards, and troubleshooting techniques necessary for ensuring high performance in cooling tower systems.

Frequently Asked Questions

What Are the Signs of Cooling Tower Problems?

Common signs include fluctuating cooling water temperatures, unusual noises from the fans, and increased energy costs. Observing these signs can help you identify potential issues early.

How Often Should Cooling Towers Be Inspected?

Cooling towers should undergo inspections at least quarterly, while some components may require more frequent checks based on usage and environmental factors.

What Role Do Water Treatments Play?

Water treatments are vital for maintaining water quality, preventing scale formation, and mitigating corrosion. Regular testing and adjustments ensure that cooling tower systems operate efficiently.

Conclusion

In summary, effectively managing cooling towers requires a comprehensive understanding of their operation, maintenance, and troubleshooting. By prioritizing maintenance routines, conducting regular inspections, and understanding common issues, organizations can enhance the operational performance of their cooling systems. Furthermore, for more extensive training on cooling tower maintenance and troubleshooting, visiting the Cooling Tower Maintenance & Troubleshooting Training Course can empower professionals to achieve higher reliability and efficiency in their cooling tower operations. Explore additional resources such as the impacts of reliability and operational performance in electric power systems at Understanding the Crucial Aspects of Reliability and Operational Performance in Electric Power Systems, or learn how to improve energy efficiency with Unlocking Energy Efficiency: A Comprehensive Guide to Energy Audit and Management Training. Each resource enriches your knowledge and skills, unlocking potential in the industrial landscape.