Table of Contents

- 1. Introduction

- 2. Understanding Process Equipment and Piping Systems

- 3. Importance in the Oil and Gas Sector

- 4. Design Considerations for Process Equipment and Piping Systems

- 5. Operational Aspects of Process Equipment

- 6. Latest Trends and Innovations

- 7. Conferences and Gatherings

- 8. FAQs

- 9. Conclusion

1. Introduction

The world of industrial processes relies heavily on process equipment and piping systems. These components are critical for the efficiency and safety of various operations, especially in sectors like oil and gas. Consequently, sharing knowledge and best practices among industry professionals becomes essential. One such event that focuses on these crucial aspects is the Process Equipment & Piping Design for Oil and Gas Conference.

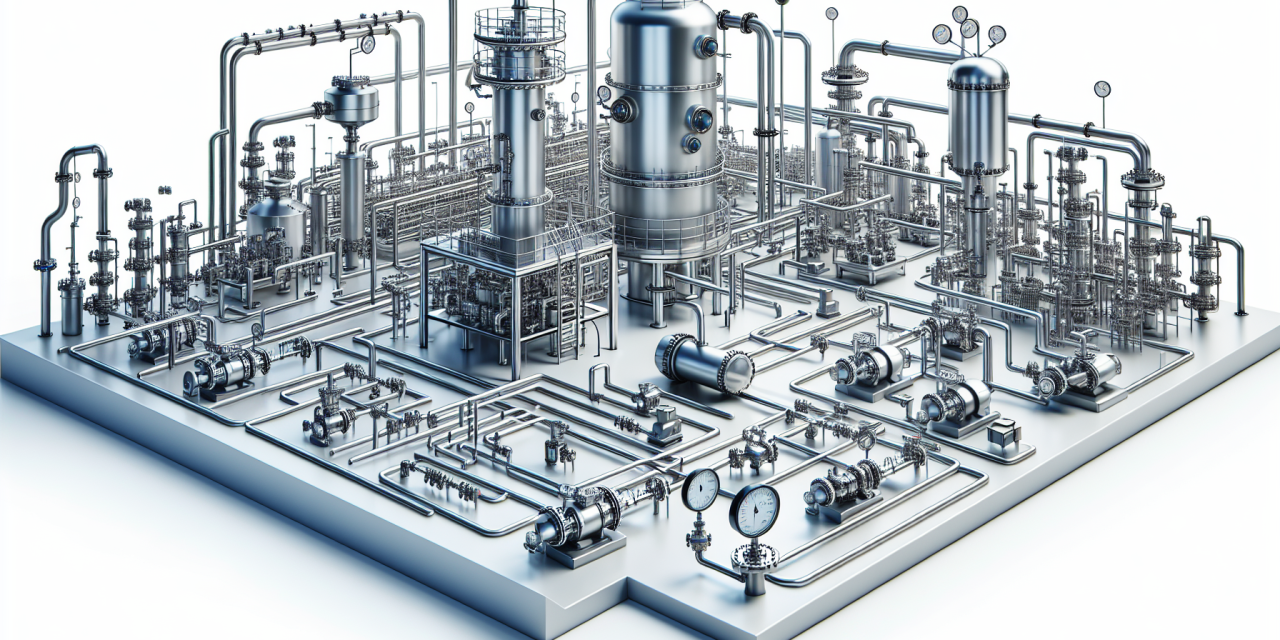

2. Understanding Process Equipment and Piping Systems

To fully grasp the importance of process equipment and piping systems, let’s take a closer look at what these terms mean. Process equipment comprises all the machinery and devices involved in manufacturing processes. On the other hand, piping systems refer to the network of pipes that transport fluids necessary for these processes.

2.1 The Role of Process Equipment

Process equipment ranges from heat exchangers and reactors to separators and pumps. Each plays a vital role in transforming raw materials into finished products. By understanding the function of each piece, professionals can better select and maintain these systems.

2.2 The Significance of Piping Systems

Piping systems facilitate the movement of substances between different process equipment. Their design is critical, as they need to handle various pressures and temperatures. Furthermore, the integrity of a piping system greatly affects the overall operational efficiency.

3. Importance in the Oil and Gas Sector

The oil and gas sector stands out as one of the most demanding industries concerning process equipment and piping systems. High pressures, extreme temperatures, and hazardous materials necessitate a thoughtful approach to design and operation.

3.1 Safety Concerns

First and foremost, safety is a major factor. Failures in equipment or piping can lead to disastrous accidents, including explosions and spills. Therefore, rigorous standards and training, such as those offered at industry conferences, play a vital role in ensuring that professionals are well-equipped to handle these challenges.

3.2 Efficiency and Cost-effectiveness

Moreover, efficient process equipment and piping systems can significantly reduce operational costs. When these systems function optimally, they minimize material loss, reduce maintenance expenses, and enhance productivity. Thus, staying updated with the latest technologies and methodologies in these areas can yield substantial financial benefits for companies.

4. Design Considerations for Process Equipment and Piping Systems

Designing process equipment and piping systems involves several key considerations to ensure functionality, safety, and longevity.

4.1 Material Selection

The choice of materials is fundamental. Engineers must consider the chemical properties of the transported substances to select materials that can withstand corrosion and other adverse reactions. This aspect is crucial for maintaining integrity over time.

4.2 Sustainability

In today’s environmentally conscious world, the sustainability of systems has gained attention. Incorporating environmentally friendly practices into design ensures the conservation of resources and reduces the ecological footprint of operations.

4.2.1 Energy Efficiency

Additionally, energy-efficient designs are gaining traction. Utilizing energy recovery systems can significantly cut down operational costs while also addressing sustainability concerns.

5. Operational Aspects of Process Equipment

Operating and maintaining process equipment and piping systems is as crucial as their design. Understanding operational best practices can help extend equipment lifespan and optimize performance.

5.1 Routine Maintenance

Regular maintenance checks are necessary to identify potential issues before they escalate. This can involve inspecting for leaks, corrosion, or any other wear that could compromise system integrity.

5.2 Training and Skill Development

Moreover, investing in training and skill development for workforce members ensures that they are adequately prepared to operate and maintain these systems. This approach boosts confidence and promotes a culture of safety.

5.2.1 Continuous Learning

Furthermore, continuous learning opportunities, such as industry conferences, provide an excellent platform for acquiring new skills and knowledge. For instance, conferences like the Process Equipment & Piping Design for Oil and Gas Conference offer insights into the latest technologies and methodologies.

6. Latest Trends and Innovations

The field of process equipment and piping systems is continually evolving. Staying informed about the latest trends is critical for professionals who wish to remain competitive in the industry.

6.1 Automation and Smart Technologies

Automation has made significant strides. Smart technologies facilitate the monitoring and control of systems, allowing for real-time data analysis. As a result, companies can enhance efficiency and reduce downtime.

6.2 Advanced Materials

Additionally, the development of advanced materials has paved the way for more durable and lightweight process equipment. These innovations contribute to improving operational efficiency while reducing maintenance needs.

7. Conferences and Gatherings

Conferences present fantastic opportunities for networking and knowledge exchange. Attending these gatherings allows industry professionals to share best practices, learn about innovations, and form valuable connections.

7.1 Importance of Networking

Networking can lead to collaborations that drive innovation. Engaging with peers can stimulate new ideas and drive industry growth, making these events valuable investments of time and resources.

7.2 Featured Events

In addition to the Process Equipment & Piping Design for Oil and Gas Conference, other informative events include:

- Harnessing the Power of Mind, Attitude & Motivation

- Unlocking Professional Excellence Through Insights

- Unlock Your Leadership Potential

- Exploring Innovations in Control Systems

- Unveiling Fluid Flow Control Systems

8. FAQs

8.1 What topics are typically covered at the Process Equipment and Piping Systems Conference?

The conference typically addresses various topics such as design best practices, safety measures, technological advancements, and operational efficiency.

8.2 How can attending conferences benefit my career?

Attending conferences can enhance your knowledge, expand your professional network, and provide insights into industry trends, all of which can significantly boost your career prospects.

8.3 Is it important to keep updated with trends in process equipment and piping systems?

Absolutely! Staying updated helps professionals implement the latest technologies, optimize performance, and maintain a competitive edge in the industry.

9. Conclusion

In conclusion, the fields of process equipment and piping systems are vital to many industries, particularly oil and gas. As technology evolves, so too must the methodologies surrounding design, operation, and maintenance. Engaging with fellow professionals through events like the Process Equipment & Piping Design for Oil and Gas Conference not only enhances knowledge but also fosters collaboration and innovation within the industry. Therefore, taking the time to invest in conferences and ongoing education is crucial for anyone wishing to excel in this field.