Table of Contents

- Introduction

- Importance of Safe Operation and Maintenance

- Understanding Circuit Breakers and Switchgear

- Safe Operation of Circuit Breakers and Switchgear

- Regular Maintenance Practices

- The Role of Training and Skills Development

- Conclusion

- FAQs

Introduction

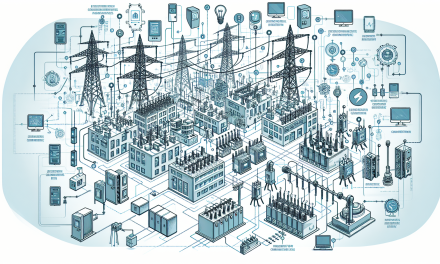

Ensuring the safety and efficiency of electrical systems deeply depends on the proper operation and maintenance of circuit breakers and switchgear. As the backbone of electrical distribution, the effectiveness of these components determines the reliability of power systems.

Importance of Safe Operation and Maintenance

When one considers the vast amount of energy managed within electrical grids, the necessity for safety cannot be overstated. Moreover, circuit breakers and switchgear serve as critical protective measures, interrupting excess current to prevent fires and equipment damage. Hence, their safe operation and maintenance guarantee not merely compliance with regulatory standards but also the safety of personnel and the longevity of the electrical components.

Understanding the Risks

Consequently, failure in these systems may lead to catastrophic consequences. Electrical faults, such as short circuits or overload conditions, can create hazardous situations, making regular checks and adherence to safety protocols imperative.

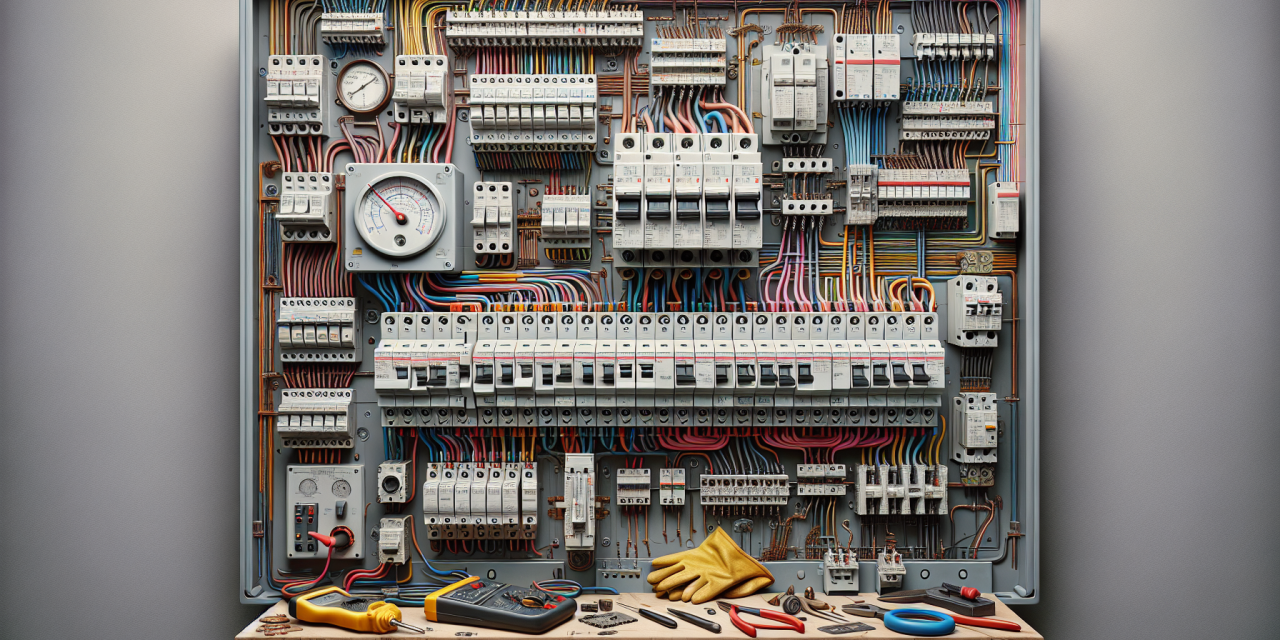

Understanding Circuit Breakers and Switchgear

Circuit breakers act as automatic switches designed to protect circuits from overloads. In contrast, switchgear represents the combination of electrical disconnects, fuses, switches, and circuit breakers used for protecting and isolating electrical equipment. Together, they ensure optimal performance while minimizing risks.

Types of Circuit Breakers and Switchgear

Several varieties of circuit breakers exist, including air-operated, oil-operated, and vacuum circuit breakers. Each type has distinct operational features that help in managing different power levels. Similarly, switchgear can be grouped into different operational categories, ranging from low-voltage to high-voltage systems.

Operational Characteristics

The operational characteristics vary significantly among types. For instance, vacuum circuit breakers are known for their quick interruption capabilities. Conversely, air-insulated switchgear is favorable in situations with limited space availability. It is essential to understand these variations when working with such equipment.

Safe Operation of Circuit Breakers and Switchgear

To achieve safety in operations, personnel must follow established guidelines meticulously. Implementing comprehensive training ensures that workers understand the equipment they are handling. Consequently, skills in detecting faults and understanding electrical diagrams become crucial in enhancing workplace safety.

Key Safe Operational Practices

- Always wear appropriate personal protective equipment (PPE) when operating circuit breakers and switchgear.

- Maintain a clear understanding of electrical diagrams and lockout/tagout procedures.

- Regularly inspect equipment for signs of wear and tear, especially insulation and connections.

- Always adhere to the manufacturer’s operational guidelines and ensure proper training is provided to all personnel.

Emergency Procedures

Ensuring familiarity with emergency procedures is equally as important. Workers should know how to react swiftly in case of electrical system failures, following established protocols for safe disconnection and reporting faults.

Regular Maintenance Practices

Engaging in regular maintenance checks helps avert malfunctions, leading to a longer life for circuit breakers and switchgear. Implementing a systematic maintenance plan undoubtedly reduces the risk of failure and enhances equipment reliability.

Routine Inspection and Testing

Conducting routine inspections enables personnel to identify potential issues before they escalate. Additionally, periodic testing of circuit breakers helps to verify their operational readiness. This proactive approach not only protects equipment but also ensures safe operation.

Documentation and Record Keeping

Meticulous documentation of inspections and maintenance activities aids in transparency and accountability. Furthermore, records can highlight recurring issues, leading to more effective troubleshooting and repairs.

The Role of Training and Skills Development

Investing in comprehensive training for personnel stands as one of the most significant actions companies can take in safeguarding operations. Skilled technicians contribute immensely to minimizing risks and enhancing efficiency.

Continuous Development of Skills

Moreover, pursuing continuous education ensures technicians stay abreast of innovations and changes in technology. Training programs that focus on the Safe Operation & Maintenance of Circuit Breakers & Switchgear Course play a proactive role in updating skills and enhancing safety practices.

Workplace Culture of Safety

Fostering a workplace culture that prioritizes safety contributes to a more secure working environment. Encouraging open communication about safety practices empowers employees to voice concerns and suggestions, ultimately leading to safer operations.

FAQs

What are the most common issues that occur with circuit breakers and switchgear?

Common issues include tripping due to overload, wear and tear of components, and poor connections that can lead to electrical failures.

How often should circuit breakers and switchgear be tested?

It’s advisable to conduct thorough testing at least annually. However, frequent checks depend on the operational conditions and the manufacturer’s recommendations.

Why is training essential for personnel dealing with circuit breakers and switchgear?

Training reduces the likelihood of accidents by equipping personnel with the necessary knowledge and skills to operate and maintain these critical systems safely.

Conclusion

In summary, understanding the safe operation and maintenance of circuit breakers and switchgear is fundamental for any organization managing electrical systems. By adhering to safety protocols, actively participating in training programs, and engaging in regular maintenance practices, companies can significantly reduce risks while ensuring optimal performance. For further insights on innovation in energy systems, consider exploring the details in articles such as Evolving Power Generation: Innovations in Gas Turbines, Combined Cycle, Wind, and Solar Technologies. Staying informed about these advancements positions organizations to adapt and thrive in an increasingly complex technological landscape.