Table of Contents

- 1. Introduction

- 2. Importance of Pipeline Operations and Maintenance

- 3. Key Components of Pipeline Operations

- 4. Maintenance Strategies for Pipelines

- 5. Safety Training in Pipeline Operations

- 6. Technology in Pipeline Maintenance

- 7. Certification in Oil and Gas Pipeline Maintenance and Operations

- 8. FAQs

- 9. Conclusion

1. Introduction

In the dynamic world of oil and gas, pipelines represent a crucial infrastructure element, delivering vital resources across vast distances. Understanding the intricacies of pipeline operations and maintenance is essential for ensuring efficiency, safety, and longevity in these systems. With the industry’s complexity and constant technological advancements, continuous learning becomes paramount.

2. Importance of Pipeline Operations and Maintenance

Firstly, properly maintained pipelines play a pivotal role in minimizing operational disruptions and preventing environmental incidents. Moreover, regular maintenance not only enhances efficiency but also reduces operational costs. Additionally, aligning with regulations protects companies from fines and enhances their reputation.

The Economic Impact

Furthermore, well-maintained pipelines ensure a steady flow of resources, which directly impacts the economy. By preventing leaks and failures, businesses save on emergency repairs and loss of product, thereby boosting profitability.

Environmental Considerations

Not to mention, pipeline operations significantly affect the environment. Training in pipeline maintenance equips professionals with the skills to implement effective measures that mitigate environmental risks. Thus, investing in knowledge pays dividends in both environmental stewardship and risk management.

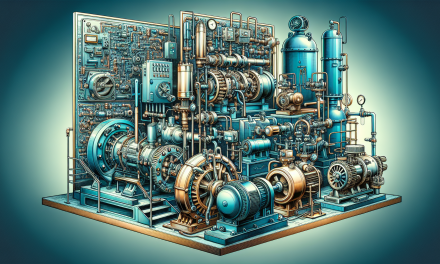

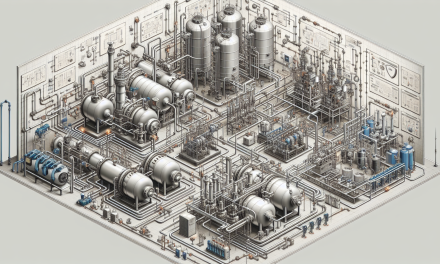

3. Key Components of Pipeline Operations

The essential components of pipeline operations encompass various elements, from planning to execution. Let’s delve into some of these key aspects.

Planning and Design

First and foremost, pipeline planning and design require meticulous attention to detail. Engineers consider factors, such as terrain, material selection, and pressure requirements. Consequently, the design must accommodate the operational conditions expected throughout its lifecycle.

Inspection and Monitoring

In addition, regular inspections and monitoring are crucial. Advanced technologies, such as smart pigging, help detect leaks and corrosion within pipelines. This proactive approach ensures that issues are identified and addressed before they escalate into serious problems.

Maintenance and Repair

Moreover, maintenance involves systematic activities, ranging from routine checks to emergency repairs. Well-documented maintenance schedules contribute to operational consistency and reliability.

4. Maintenance Strategies for Pipelines

Implementing effective maintenance strategies can transform pipeline operations. Here are several approaches that prove beneficial.

Preventive Maintenance

For starters, preventive maintenance consists of regular inspections and addressed issues before they become significant challenges. This strategy not only prolongs the life of the pipeline but also enhances safety.

Predictive Maintenance

On the other hand, predictive maintenance leverages data analytics and monitoring tools. By analyzing trends, professionals can anticipate when maintenance should occur, thus minimizing unplanned downtime.

Corrective Maintenance

Lastly, corrective maintenance comes into play after an issue arises. While this approach is reactive, having a comprehensive action plan mitigates adverse effects from unexpected failures.

5. Safety Training in Pipeline Operations

Safety remains a top priority in pipeline operations. Therefore, specialized training equips personnel with the knowledge and skills necessary to handle hazardous situations effectively.

Understanding Risks

To begin with, participants learn about the risks associated with pipeline operations, including chemical exposure and environmental hazards. Furthermore, understanding these risks facilitates implementing safety measures.

Emergency Response Training

Additionally, training must include emergency response protocols. The ability to react swiftly and appropriately can significantly minimize harm in a crisis.

Regulatory Compliance

Moreover, training focuses on compliance with industry regulations. Understanding legal requirements helps organizations avoid penalties and maintain operational licenses.

6. Technology in Pipeline Maintenance

Technology plays an undeniable role in enhancing the efficiency and safety of pipeline operations. Breaking through traditional methods has led to significant advancements.

Automation and Robotics

Robotics and automation streamline inspection processes, enabling more frequent and accurate assessments. For instance, drones can provide aerial views, while robots may traverse pipelines to inspect internal conditions.

Data Analytics

Furthermore, data analytics offers invaluable insights. By harnessing large data sets, organizations can identify patterns and predict maintenance needs, leading to improved decision-making.

7. Certification in Oil and Gas Pipeline Maintenance and Operations

Obtaining certification in oil and gas pipeline maintenance and operations enhances both individual and organizational credibility. A recognized certification, such as the Oil & Gas Pipeline Maintenance & Operations Certification, signifies expertise and a commitment to industry standards.

Benefits of Certification

Firstly, certification improves a professional’s marketability, showcasing their skills to potential employers. Secondly, it promotes a culture of continuous improvement within organizations, driving excellence in practices.

Staying Updated

Moreover, certification programs often provide up-to-date information on regulations and best practices. Thus, professionals remain informed about emerging trends impacting the industry.

8. FAQs

What are the key skills needed for pipeline operations and maintenance?

Key skills include understanding engineering principles, experience with inspection techniques, problem-solving abilities, and knowledge of safety regulations.

What role does technology play in pipeline maintenance?

Technology enhances efficiency through tools like smart sensors, robotics for inspections, and data analytics for predictive maintenance.

How often should pipelines be inspected?

Pipelines should undergo regular inspections based on operational conditions, with many companies adopting a schedule ranging from annually to quarterly, depending on risk factors.

Why is safety training important?

Safety training minimizes the risk of accidents and prepares personnel to respond effectively to emergencies, thus protecting lives and the environment.

What kind of certification is available?

Various certifications are available, focusing specifically on pipeline maintenance and operations, with programs that emphasize safety, efficiency, and regulatory compliance.

9. Conclusion

To sum up, oil and gas pipeline operations and maintenance is a multifaceted field requiring a blend of technical skills, safety awareness, and ongoing education. By adopting effective maintenance strategies, leveraging modern technology, and emphasizing safety training, organizations can bolster their operations. For those seeking to advance their expertise, investing in certification is a prudent move. As seen through the challenges faced in this industry, continuous learning is key, enhancing not only personal growth but also contributing to a more sustainable and efficient future for oil and gas pipeline operations. Additionally, expanding knowledge further can be achieved by exploring resources like Building Envelope Inspections for Construction Professionals, Process Plant Troubleshooting, Refinery Process Yields Optimization, Safety Audit and Site Inspection Training, and Understanding Petroleum Reservoir Fluid Dynamics.