Table of Contents

- Introduction

- The Importance of Safe Operation and Maintenance

- Types of Circuit Breakers and Switchgear

- Safety Practices for Circuit Breakers and Switchgear

- Routine Maintenance: Best Practices

- Common Issues and Troubleshooting

- FAQs

- Conclusion

Introduction

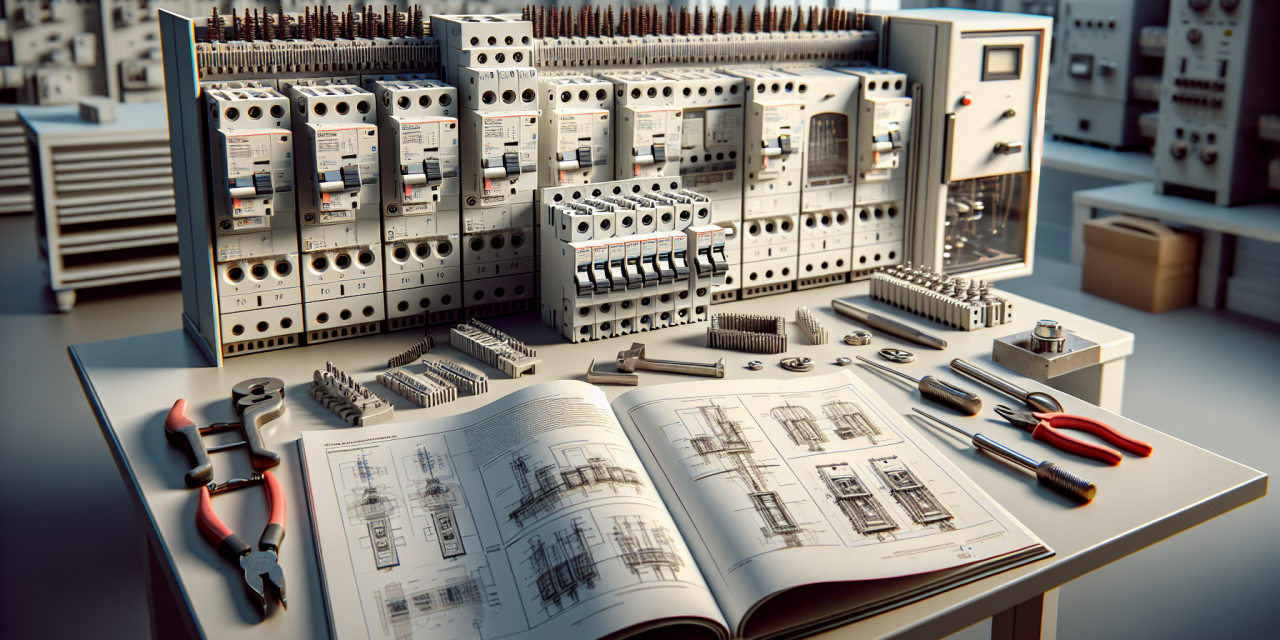

In industrial settings, circuit breakers and switchgear play a crucial role in managing electrical distribution. Therefore, ensuring their safe operation and maintenance not only protects equipment but also safeguards personnel and contributes to operational efficiency. This blog post covers key aspects of maintaining circuit breakers and switchgear, aiming to provide a comprehensive yet easy-to-follow guide.

The Importance of Safe Operation and Maintenance

Understanding the significance of proper operation and maintenance practices is vital. Safe operation minimizes the risk of equipment failure, which can lead to costly downtime, injuries, or even fatalities. Additionally, when circuit breakers and switchgear operate correctly, they enhance energy efficiency, benefitting both the environment and the bottom line.

Enhancing Equipment Longevity

Regular maintenance and careful operation directly impact the lifespan of circuit breakers and switchgear. For instance, maintaining connections and ensuring cleanliness can prevent unnecessary wear and tear. Ultimately, proactive measures reduce replacement costs and contribute to operational sustainability.

Types of Circuit Breakers and Switchgear

In discussing safe operation, it’s important to recognize the different types of circuit breakers and switchgear commonly in use. Each type has its specific operational nuances, and understanding these can enhance safety and effectiveness.

Types of Circuit Breakers

- Air Circuit Breakers (ACB): Used for high-voltage applications and known for their durability.

- Miniature Circuit Breakers (MCB): Ideal for low-voltage settings, sensitive to minor overloads.

- Residual-Current Circuit Breakers (RCCB): Vital for detecting ground faults, ensuring electrical safety.

Types of Switchgear

- Metal-Enclosed Switchgear: Designed for high voltage applications and provides excellent protection.

- Air-Insulated Switchgear: Commonly used in industrial settings due to its reliability and safety features.

- Gas-Insulated Switchgear: Highly efficient and ideal for spaces where safety is paramount.

Safety Practices for Circuit Breakers and Switchgear

Implementing prudent safety practices is non-negotiable for anyone working with circuit breakers and switchgear. Here are some essential practices to consider:

Personal Protective Equipment (PPE)

Always wear appropriate PPE, such as insulated gloves, safety glasses, and hard hats. This ensures that you remain safe while handling electrical equipment.

Lockout/Tagout Procedures

Before performing maintenance, adhere to lockout/tagout (LOTO) procedures to prevent accidental energization of the equipment. This protocol saves lives by ensuring that no one can inadvertently restart a circuit during maintenance activities.

Conduct Regular Training

When operators remain well-trained and informed about risks, the overall safety environment improves significantly. Organizing training sessions enables staff to familiarize themselves with emergency procedures, safety protocols, and changes in legislation.

Routine Maintenance: Best Practices

Regular maintenance is essential to keep circuit breakers and switchgear functioning optimally. Here are some best practices to incorporate into your routine:

Visual Inspections

Conduct visual inspections at least once a month. Look for any signs of wear, corrosion, or loose connections. Identifying issues early on can prevent more significant problems down the line.

Electrical Testing

Perform regular electrical testing to monitor the health of your equipment. This includes insulation resistance tests, contact resistance tests, and functional tests. Documentation of these tests helps track the condition of the equipment over time.

Cleaning and Lubrication

Keep circuit breakers and switchgear clean from dust and debris. Additionally, lubricate moving parts to ensure smooth operation. Remember, a clean machine is often a reliable machine!

Common Issues and Troubleshooting

Despite proper maintenance and safety practices, issues can arise. Understanding common problems can help you troubleshoot effectively:

Overheating

Overheating can signify issues like poor connections or overloading. If you notice unusual temperatures, it’s crucial to conduct further investigations immediately.

Tripped Circuit Breakers

Frequent tripping may indicate a short circuit or overload conditions. Check for faults in the circuit and rectify any issues prior to resetting the breaker.

Failure to Operate

If a circuit breaker or switchgear fails to operate when needed, it might be stuck or have internal damage. In these cases, professional inspection is mandatory.

FAQs

1. How often should I perform maintenance on circuit breakers and switchgear?

Maintenance should occur at least once a month, while thorough inspections and electrical testing are recommended annually. Regular upkeep will ensure longevity and reliability.

2. What types of PPE should be used during maintenance?

Key PPE includes insulated gloves, hard hats, safety glasses, and face shields. Your safety equipment should match the level of risk posed during your specific maintenance tasks.

3. Where can I find more information about safety operation and maintenance of circuit breakers?

For detailed insights, consider attending the Safety Operation & Maintenance of Circuit Breaker Conference. This event offers valuable discussions around safety and best practices.

Conclusion

In conclusion, safe operation and diligent maintenance of circuit breakers and switchgear are fundamental components of electrical safety in industrial settings. By adhering to best practices outlined in this blog, businesses not only protect their investments but also ensure a safe working environment for their staff. Remember, staying informed and proactive in your maintenance approach is key. Additionally, for those interested in a broader understanding of efficient machinery operation and maintenance, resources like this comprehensive guide to fluid machinery can offer further insights.

For optimization strategies, be sure to explore our discussions at fluid machinery optimization and uncover more about production planning scheduling. Additionally, expanding learning opportunities at process plant training conferences can further equip your team with essential knowledge. Finally, never underestimate the importance of effective negotiation outlined in contract negotiation seminars.