Table of Contents

- Importance of Training in Oil Production

- Key Components of Oil Production and Processing

- Emerging Technologies in Oil Production

- Safety Protocols in Processing Facilities

- Environmental Considerations

- Tailored Programs for Various Objectives

- Frequently Asked Questions

- Conclusion

Importance of Training in Oil Production

In the dynamic landscape of oil production and processing, equipping personnel with the necessary skills and knowledge has never been more crucial. The process involves numerous complex operations, each requiring specialized knowledge to ensure efficiency and safety. Investments in training yield significant returns, as they enhance productivity, reduce accidents, and ensure compliance with regulations.

Those who undergo proper training gain insights into modern practices, innovative technologies, and industry standards that govern operations. This not only nurtures a culture of safety but also fosters an environment where workers feel empowered and engaged in their roles.

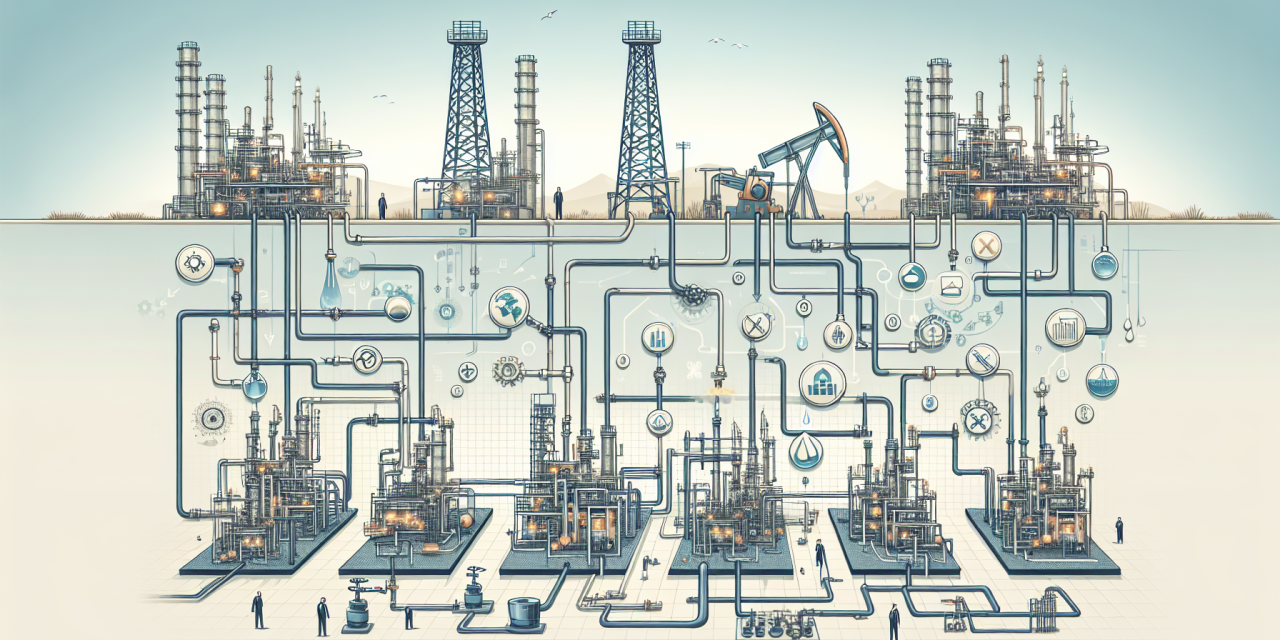

Key Components of Oil Production and Processing

Understanding the Oil Production Process

Oil production begins with exploration and drilling, where operators seek to extract crude oil from beneath the earth’s surface. This multifaceted process requires meticulous planning and execution. For instance, drilling techniques must adapt to varying geological conditions, which necessitates comprehensive training in both theory and practical applications.

Crude Oil Processing

Once extracted, crude oil undergoes processing to transform it into valuable products. This process includes distillation, where different components of crude oil separate based on boiling points. It is essential to understand these processes deeply, as they directly influence the efficiency and safety of operations.

Refining Operations

Refining operations represent a significant part of oil processing facilities. Mastering techniques such as yield optimization is key to maximizing output while minimizing costs. Numerous strategies exist, and understanding the best practices can drastically improve production efficiency. For further insights, you can dive into Maximizing Efficiency in Refinery Processes: Techniques for Yield Optimization.

Emerging Technologies in Oil Production

Adopting emerging technologies leads to more efficient oil production and processing. Industry professionals must embrace new tools, such as advanced data analytics and automation, to streamline operations. These technologies aid in monitoring equipment performance, predicting maintenance needs, and enhancing overall production quality.

Gas Chromatography Tools

Gas chromatography plays a crucial role in the oil and gas industry for quality control and troubleshooting. By understanding the techniques and best practices involved, operators can achieve greater accuracy in their assessments. For an in-depth exploration, refer to Gas Chromatography in the Oil & Gas Industry: Troubleshooting Techniques and Best Practices.

Training for Technological Proficiency

To stay ahead of the curve, training programs incorporate these technologies, ensuring that personnel remain proficient. This adaptive approach ensures that workers can leverage technological advancements effectively, thus enhancing overall productivity.

Safety Protocols in Processing Facilities

Implementing stringent safety protocols is paramount in oil production and processing facilities. The hazardous nature of the materials involved necessitates extensive safety training for all personnel.

Creating a Safety Culture

Establishing a culture of safety requires ongoing education and a commitment from management and employees alike. Regular training sessions that focus on the identification and mitigation of hazards can foster an environment where safety takes precedence. Such proactive measures not only protect workers but also safeguard the environment and the community.

Environmental Considerations

As the oil and gas industry continues to evolve, environmental considerations have gained prominence. Operators must navigate increasingly stringent regulations designed to protect the environment, and understanding these requirements is critical.

Training for Environmental Compliance

Training programs that emphasize environmental stewardship enable workers to recognize their role in sustainable practices. Topics such as spill response, waste management, and emissions control are essential components of such training. Interested readers can explore how to manage marine terminal operations in a safe and environmentally friendly manner via Unlocking the Secrets of Oil & Gas Marine Terminal Operations.

Tailored Programs for Various Objectives

It’s crucial to acknowledge that training needs can vary significantly across organizations and roles in the oil industry. Tailored programs that address specific operational objectives lead to more effective outcomes. Custom courses can focus on refining techniques, safety protocols, or even emergency response strategies, depending on the unique challenges faced by each facility.

Personalized Learning Experiences

By providing personalized learning experiences, companies can enhance employee engagement and retention of knowledge. For instance, a facility focused on power generation can benefit from specialized training on steam turbines and gas turbines. Those seeking comprehensive knowledge can visit Understanding Power Generation: A Comprehensive Guide to Steam Turbines, Gas Turbines, and Combined Cycle Power Plants.

Frequently Asked Questions

1. What are the benefits of comprehensive training in oil production and processing?

Comprehensive training equips personnel with the skills needed to improve efficiency, enhance safety, and adapt to evolving technologies in the industry.

2. How can my facility benefit from tailored training programs?

Tailored training programs address specific operational needs and challenges, promoting better understanding and engagement among employees, ultimately leading to improved outcomes.

3. What role do emerging technologies play in training programs?

Emerging technologies are integrated into training programs to ensure personnel are proficient in using modern equipment and techniques, leading to more efficient operations.

4. How important is safety training in the oil production industry?

Safety training is critical in the oil production industry due to the hazardous nature of materials and processes involved. A strong safety culture reduces accidents and ensures compliance.

5. Where can I find comprehensive training related to oil production?

You can explore opportunities and resources at the Oil Production & Processing Facilities Training Course, which provides valuable insights into best practices in the industry.

Conclusion

In summary, emphasizing training in oil production and processing facilities has a profound impact on operational efficiency, safety, and compliance with environmental standards. By investing in comprehensive education for personnel, organizations contribute to a more skilled labor force equipped to handle the complexities of the oil industry. Tailored programs, incorporating emerging technologies and safety protocols, enhance the overall effectiveness and sustainability of oil production operations.