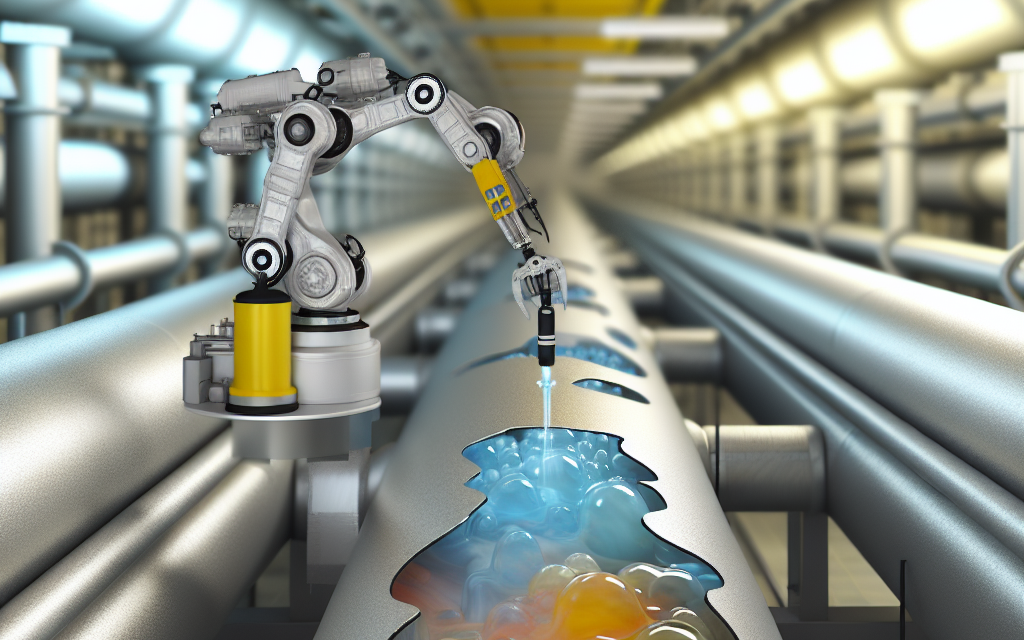

Effective Corrosion Control in Gas, Oil & Water Management

Corrosion poses a serious threat to the infrastructure of gas, oil, and water sectors. Therefore, effective corrosion control is essential to ensure safety and efficiency. Understanding how to properly manage corrosion can greatly enhance operational sustainability. Let’s explore the significance of corrosion control and the strategies companies are using to tackle this persistent challenge.

Why Corrosion Control Matters

Corrosion affects pipelines, tanks, and other critical components in the energy and utilities industries. As a result, companies face risks such as leaks, failures, and environmental hazards. By investing in solid corrosion control practices, organizations can avoid costly repairs and safeguard their assets.

Understanding Corrosion Mechanisms

Corrosion occurs due to the interaction between metals and their surrounding environment. Factors like moisture, temperature, and chemical exposure play pivotal roles. Therefore, understanding these mechanisms is fundamental in preventing corrosion-related issues. For detailed insights, check out this Essential Guide to Electrical Power System Protection.

Implementing Effective Strategies

Many companies are embracing robust strategies to combat corrosion. For instance, regular inspections and monitoring can help identify potential weaknesses early on. Additionally, adopting innovative technologies significantly enhances corrosion resistance. If your organization seeks to drive strategy with leadership innovation and execution, you might find this resource helpful.

Training and Development in Corrosion Management

With the industry continuously evolving, training is essential. Professionals constantly need to update their knowledge and skills, particularly regarding corrosion control. Workshops and seminars can provide valuable information on the latest techniques and technologies.

Corrosion Control in Gas, Oil & Water Management

For specialized training, the Corrosion Control in Gas, Oil & Water Training Course delves deeply into prevention tactics and best practices. Participants learn how to mitigate risks and develop effective maintenance plans that ensure infrastructure longevity.

The Role of Leadership in Corrosion Strategy

Leadership plays a critical role in guiding teams towards effective corrosion management. A unified vision fosters innovative thinking and encourages the adoption of proactive measures. Discover how leadership drives strategic innovation in this insightful post: Leadership in Driving Strategic Innovation.

FAQs

What are the common methods of corrosion control?

Common methods include cathodic protection, coatings, and material selection. Each method provides unique benefits and should be chosen based on specific environmental conditions and application.

How often should corrosion inspections be conducted?

Regular inspections should occur annually or semi-annually, depending on the environment and criticality of the assets. Consistent monitoring helps catch problems before they escalate.

Conclusion

Corrosion control is a vital aspect of maintaining the integrity of gas, oil, and water systems. With effective strategies and ongoing training, organizations can navigate this challenge successfully. Remember, proactive measures not only prevent costly repairs but also ensure safer and more reliable operations.

For further training resources on power system reliability, consider exploring Master Power System Protection Reliability: Essential Training and Master Power System Protection Reliability.