Table of Contents

- 1. Introduction

- 2. What Are Process Equipment and Piping Systems?

- 3. Applications of Process Equipment and Piping Systems

- 4. Design Considerations in Process Equipment and Piping Systems

- 5. Operation and Maintenance

- 6. Challenges in Process Equipment and Piping Systems

- 7. FAQs

- 8. Conclusion

1. Introduction

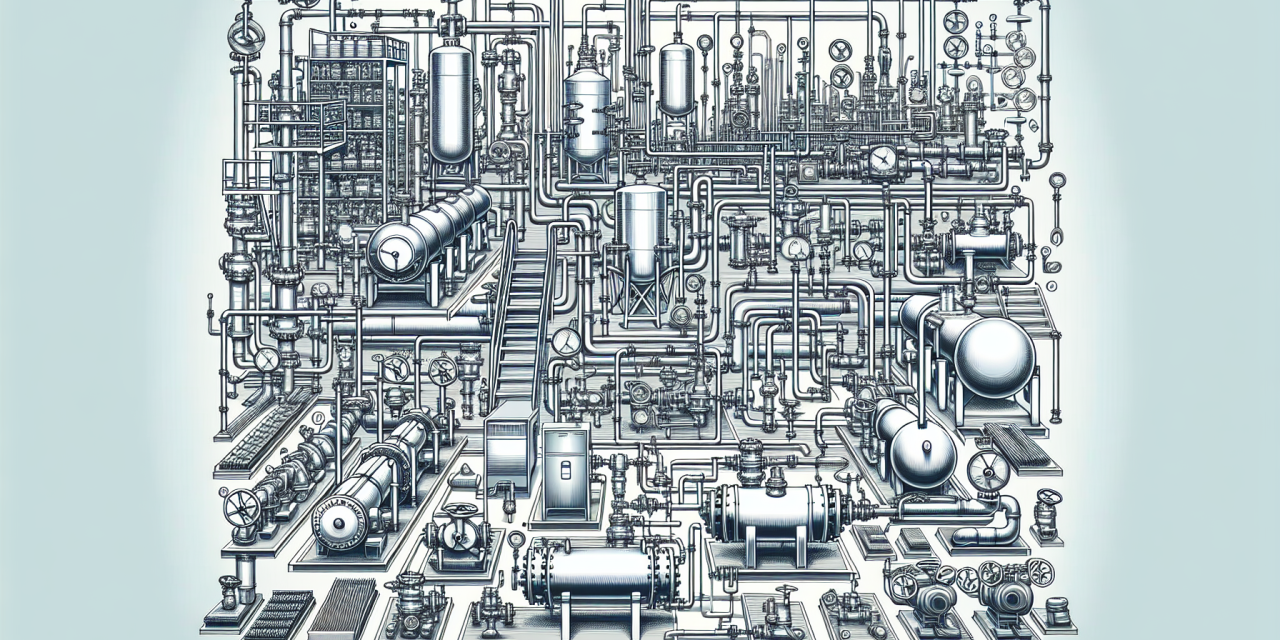

Process equipment and piping systems form the backbone of various industrial applications, playing a crucial role in the efficient movement and processing of materials. These systems facilitate productivity while ensuring safety and compliance with industry standards. Hence, understanding their design, application, and operation is essential for engineers and technical professionals.

2. What Are Process Equipment and Piping Systems?

To begin with, process equipment refers to an array of machinery used to produce, process, or handle materials. This encompasses equipment like ***reactors***, ***heat exchangers***, ***pumps***, and ***compressors***. In contrast, piping systems are the networks of pipes and fittings that transport fluids and gases between different units of process equipment.

Types of Process Equipment

Common types of process equipment include:

- Reactors: Used for chemical reactions.

- Separators: Used to separate different phases of materials.

- Pumps: Equipment for moving fluids.

- Compressors: Increase the pressure of gases.

- Heat Exchangers: Transfer heat between fluids.

Piping System Essentials

Piping systems are composed of various components, including:

- Pipes: The main conduit for fluids.

- Fittings: Used to connect sections of pipe.

- Valves: Control the flow and pressure of fluids.

- Supports: Maintain the structure of pipe systems.

3. Applications of Process Equipment and Piping Systems

Process equipment and piping systems are widely utilized across several industries.

Chemical Industry

In the chemical sector, these systems efficiently facilitate the production of various substances, ensuring safe handling of reactive and hazardous materials.

Oil and Gas Sector

These systems play a critical role in extraction, refining, and transportation processes. For instance, in oil refineries, complex piping networks transport crude oil and its derivatives.

Pharmaceuticals

Precise engineering in process equipment and piping systems is vital in the pharmaceutical industry to ensure drug quality and compliance with stringent regulations.

Power Generation

Power plants utilize piping systems extensively for steam, cooling water, and other critical fluids to optimize efficiency and safety.

4. Design Considerations in Process Equipment and Piping Systems

Designing process equipment and piping systems requires careful attention to several key factors, ensuring efficient operation and safety.

Process Requirements

Initially, understanding the specific requirements of the process is essential. This includes considering temperature, pressure, flow rates, and the chemical properties of the materials being handled.

Material Selection

Selecting appropriate materials is another critical design aspect. Different materials resist corrosion and heat better than others, making material selection vital for longevity and safety.

Standard Compliance

Designers must also adhere to industry standards and regulations to ensure compliance. These standards dictate the safety and reliability of equipment and systems.

Safety Considerations

In addition to complying with standards, incorporating safety features into the design process are crucial. This includes pressure relief valves, emergency shut-off systems, and leak detection methods.

5. Operation and Maintenance

Operational efficiency significantly relies on rigorous maintenance practices.

Training and Skills Development

Equipping personnel with appropriate training ensures proficient operation of process equipment and piping systems. Continuous improvement in skills can lead to enhanced operational performance.

For those interested in formal training, opportunities such as the Process Equipment & Piping System Design and Operation Course can provide valuable insights.

Regular Inspections

Conducting routine inspections plays a pivotal role in identifying potential problems before they escalate. This proactive maintenance approach contributes to system longevity.

Predictive Maintenance

Utilizing technologies such as sensors and monitoring software allows for predictive maintenance. This technology helps predict when equipment is likely to fail, enabling timely interventions.

6. Challenges in Process Equipment and Piping Systems

Several challenges may arise in the design, application, and operation of these systems.

Wear and Tear

Over time, wear and tear occur due to continuous operation. Understanding this phenomenon and implementing maintenance can help mitigate potential issues.

Corrosion

Corrosion poses a significant challenge in piping systems, particularly in harsh chemical environments. Selecting the right materials and employing protective coatings can help combat corrosion.

Complexity of Systems

The intricate nature of process equipment and piping systems can lead to challenges in identifying malfunctions. Implementing a systematic approach to troubleshooting enhances system reliability. Explore more about troubleshooting in the following resource: Mastering Process Plant Troubleshooting and Engineering Problem-Solving for Optimal Performance.

7. FAQs

What are the key components of a piping system?

The key components of a piping system include pipes, fittings, valves, and supports.

How do I choose the right materials for process equipment?

Choosing the right materials involves assessing the chemical properties, temperature, and pressure of the substances involved.

What is the importance of regular maintenance?

Regular maintenance ensures the system operates efficiently and safely, preventing potential issues before they escalate.

Where can I learn more about the fundamentals of mechanical engineering technology?

To gain insights into the principles of mechanical engineering technology, check out Exploring the Fundamentals of Mechanical Engineering Technology: A Comprehensive Guide.

8. Conclusion

In summary, process equipment and piping systems serve essential roles in various industries. Their effective design and operation hinge on understanding the principles of fluid dynamics, thermodynamics, and safety regulations. By incorporating best practices and innovative technologies, professionals can enhance performance and maintain safety standards. Furthermore, additional resources like Unlocking the Essentials of Process and Mechanical Technology for Optimal Performance and Navigating the Complexities of Petroleum Laboratory Management in Oil and Gas Operations are valuable for reinforcing knowledge in this dynamic field. Moreover, acquiring management skills through articles like Mastering Essential Skills for Effective Management in the Oil and Gas Sector can further benefit professionals in navigating the complexities of their roles.