Table of Contents

Introduction

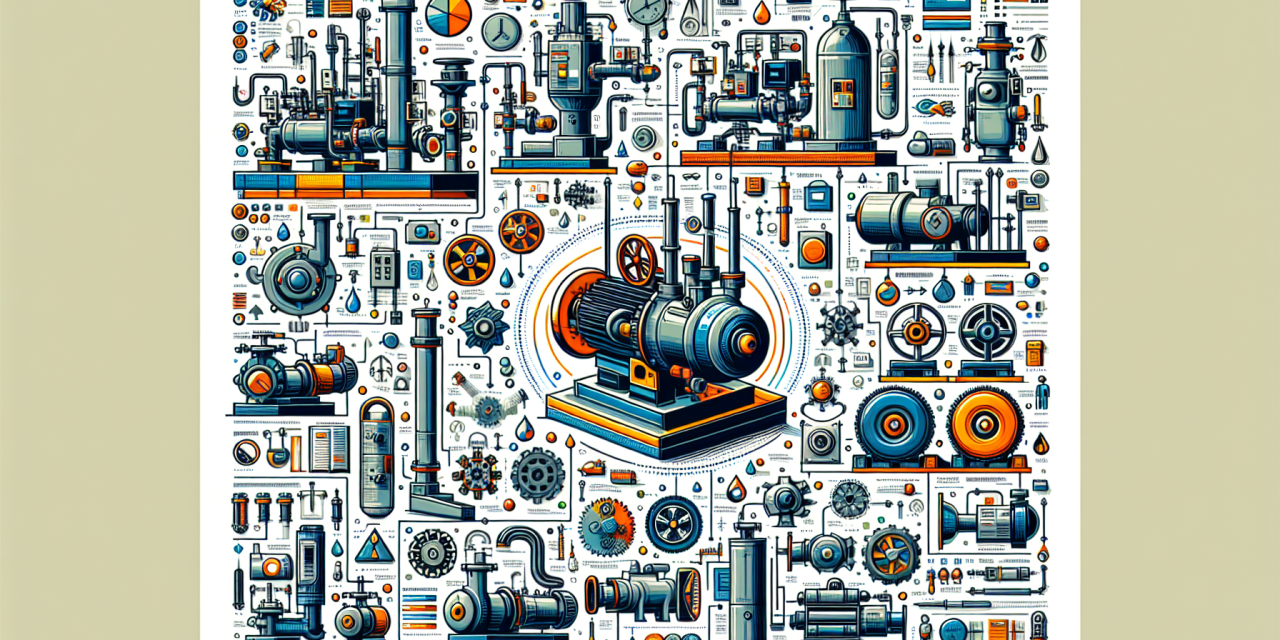

Fluid machinery plays a significant role in various industries, particularly in process plants, petroleum refineries, and other critical applications. This guide delves into the selection, operation, and maintenance of pumps, compressors, and turbines, focusing on practical insights and best practices.

Overview of Fluid Machinery

Fluid machinery comprises devices that transport fluids or compress gases, efficiently converting energy. Typically, these machines fall into three distinct categories: pumps, compressors, and turbines. Each type serves specific functions and applications while enabling industries to optimize their processes.

Pumps

Pumps are vital for moving liquids through pipelines and systems. They come in various types, each designed for specific applications. Selecting the right pump is crucial for operational efficiency and longevity.

Types of Pumps

The primary types of pumps include:

- Centrifugal Pumps: They utilize rotational energy to move fluids, often used for water and chemical transfer.

- Positive Displacement Pumps: These pumps trap a fixed volume of fluid and force it out, making them ideal for pumping viscous liquids.

Selection Criteria for Pumps

Choosing the right pump involves considering several factors, including:

- Fluid Characteristics: Understand the viscosity, temperature, and chemistry of the fluid being pumped.

- Flow Rate: Determine the required flow rate to match the system needs.

- Pressure Requirements: Assess the system’s pressure requirements to ensure the pump can generate sufficient head.

Operation and Maintenance of Pumps

Regular maintenance extends the pump’s life and ensures optimal performance. Important practices include:

- Regularly checking seals and bearings for wear.

- Monitoring the pump’s performance metrics, such as flow rate and pressure.

- Performing routine cleaning to remove debris that could clog the pump.

Compressors

Compressors are essential for increasing the pressure of gases and are commonly found in refrigeration, air conditioning, and natural gas processing.

Types of Compressors

Compressors generally fall into two categories:

- Positive Displacement Compressors: These work by trapping a specific amount of air and then reducing the volume, which increases pressure.

- Centrifugal Compressors: They use the rotational motion of blades to compress gases, suitable for high flow rates.

Selection Criteria for Compressors

When selecting a compressor, consider the following:

- Application: Identify the purpose of the compressor to determine the type needed.

- Capacity and Pressure: Evaluate the required capacity and system pressure to ensure compatibility.

- Efficiency: Opt for energy-efficient models to reduce operational costs.

Operation and Maintenance of Compressors

To maintain compressor efficiency, practice the following:

- Regularly check for leaks in piping and fittings.

- Keep the area around the compressor clean and free of obstruction.

- Schedule regular inspections and servicing by qualified technicians.

Turbines

Turbines convert energy from fluids into mechanical work, widely used in power generation and propulsion systems.

Types of Turbines

The most common types of turbines include:

- Steam Turbines: They utilize steam to drive machinery, playing a major role in power plants.

- Gas Turbines: These are ideal for jet engines and electricity generation, using hot gases to produce thrust or mechanical energy.

Selection Criteria for Turbines

Key factors for turbine selection involve:

- Operating Conditions: Evaluate the temperature and pressure of the working fluid to find a compatible turbine.

- Efficiency: Choose turbines that offer superior thermal and mechanical efficiency.

- Application Specifics: Understand your specific industry requirements, be it power generation or propulsion.

Operation and Maintenance of Turbines

Effective maintenance programs can enhance turbine reliability and performance:

- Monitor vibration and temperature levels closely.

- Regularly inspect components for wear and corrosion.

- Keep the system clean to avoid operational inefficiencies.

Fluid Machinery Conference: Pumps, Compressors & Turbines Mastery

Participating in a conference dedicated to fluid machinery can significantly enhance your knowledge and skills. The Fluid Machinery Conference: Pumps, Compressors & Turbines Mastery focuses on the latest trends, technologies, and operational strategies essential for engineers and technicians in the industry.

FAQs

What are the main differences between pumps and compressors?

Pumps primarily move liquids, while compressors focus on increasing the pressure of gases. Each has unique mechanisms suited to different types of fluid dynamics.

How can I determine the right pump or compressor for my application?

Assess the physical properties of the fluid—such as viscosity and temperature—as well as the operational requirements, including flow rate and pressure.

What maintenance practices should be in place for turbines?

Regular checks for efficiency, monitoring operational metrics, and preventive maintenance schedules are essential to ensure turbine longevity.

Conclusion

Efficiently selecting, operating, and maintaining fluid machinery profoundly impacts productivity and sustainability across multiple industries. By prioritizing proper practices and gaining insights from industry conferences, professionals can enhance their capabilities and contribute to the operational excellence of their organizations. For further reading on optimizing selection, operations, and maintenance of these vital machines, check out Fluid Machinery: Optimizing the Selection, Operation, and Maintenance of Pumps, Compressors, and Turbines.

Additionally, learn about the importance of planning and scheduling in refineries with Unlocking Efficiency: The Importance of Production Planning & Scheduling in Petroleum Refineries, and discover essential insights into process plant operations through the Essential Insights into the Process Plant Start-Up & Commissioning Training Conference.

Finally, to master negotiation and contract drafting, explore Master the Art of Negotiating and Drafting Contracts, and elevate service quality with insights from Enhancing Service Quality and Elevating Customer Satisfaction.